Case Study

Settsu Inc.

Installation of a system that automatically controls LED lighting with monitoring cameras.

Detects worker movements and adjusts lighting for enhanced energy savings.

Chemicals

Environmental measure, Improved safety, Lower costs

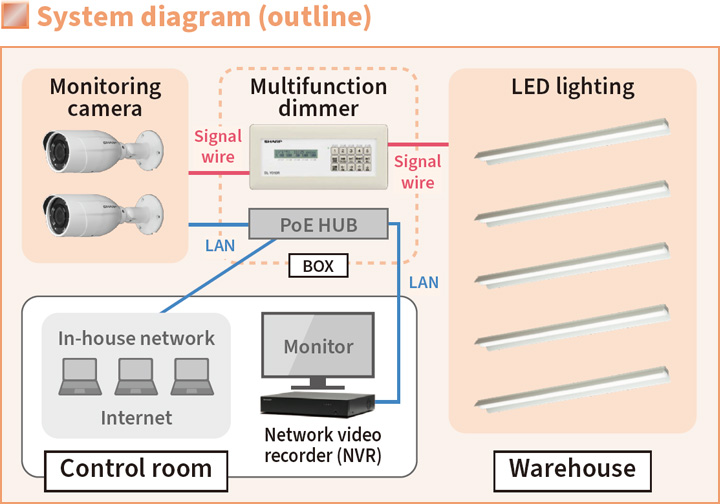

LED lighting: DL-MU400N+DL-M610M × 44 units

Multifunction dimmer: DL-Y010R × 2 units

Network camera: YK-B02AF × 4 units

Network video recorder: YC-R08B4 × 1 unit

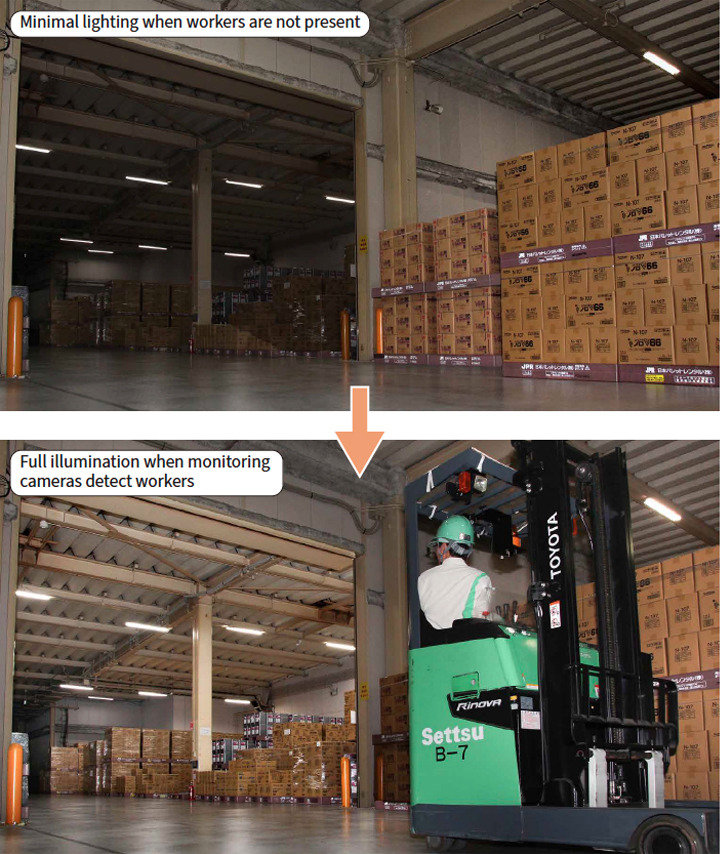

Installation in two rooms of a logistics warehouse. Began operation in May 2023. Power consumption is reduced with a system that uses cameras to detect the movement of people and forklifts and then automatically controls LED lighting brightness accordingly.

Sakai City, Osaka Prefecture

Established in 1889. A member of the Nisshin OilliO Group. A participant in the oils and fats business since its establishment, Settsu Inc. also provides other products and services in its hygiene management business, which includes cleaning agents and sanitizers, and other businesses in response to a wide range of needs.

We are promoting the use of clean energy and energy conservation as part of our ESG management. One path we took to achieve this goal was to progressively switch to LED lighting in our factories and warehouses. However, we were looking for a new system that could automatically control lighting as needed to achieve even more energy savings.

- Monitoring cameras detect workers and automatically adjust lighting accordingly. This has resulted in significant energy savings.

- The system provides sufficient light when workers are present as it also saves electricity. It makes warehouse picking work easier.

- Because the system uses monitoring cameras, it is also helpful in product management as well as worker health and safety management.

Balancing energy savings and brightness with lighting.

As a member of the Nisshin OilliO Group, we are working on decarbonizing our operations under the Group’s ESG management policy by promoting the use of clean energy and energy conservation. One way we are moving to reduce our power consumption is by progressively switching to LED lighting in our factories and warehouses. But while working to save energy, we also understood that supplying sufficient lighting is essential to ensuring quality control in our factories as well as accuracy and safety during picking in our warehouses. The challenge was to balance energy savings and brightness.

Takashi Sawada

Corporate Officer

General Manager

Supply Chain Department

Settsu Inc.

The system saves energy and also monitors worksites.

When we were studying whether there were ways to automatically turn lighting on and off as needed to achieve both energy savings and brightness, Sharp presented us with an energy-saving proposal that used monitoring cameras to detect forklifts and people as they entered, exited, or stayed in buildings and then automatically adjusted LED lighting brightness accordingly. We thought that was a very innovative idea. Unlike with sensors, the system uses monitoring cameras whose images can be checked and recorded in the control room. So we thought it would be simultaneously useful for strict product management and worker health and safety management.

The monitoring cameras detect motion and automatically adjust lighting, even in large spaces with high ceilings.

Forklifts move around the warehouse, which is divided into several areas, to pick product cases. When a camera detects a forklift entering its area, the LED lighting in that area becomes brighter, and when it detects the forklift leaving the area, the lighting gradually dims to its lowest level. Because the system automatically adjusts lighting according to the presence or absence of workers, it saves energy beyond what could be achieved by simply switching to LED lighting. And onsite workers are happy that their workplaces are brighter and easier to work in. In addition, the images provided by the monitoring cameras allow us to constantly observe conditions in the warehouse, helping us create a safe working environment.

A new solution for logistics warehouses created by linking Sharp products

Drawing attention to the system as an energy-saving and quality assurance initiative.

This state-of-the-art system will enhance the public’s image of our logistics warehouses. In view of this, we intend to further increase the number of areas in which it is installed and even make greater use of it in our personnel recruiting and hiring. At the same time, we will broadly publicize this energy-saving measure as an ESG management-related practice and also draw our customers’ attention to it as an initiative that ensures quality from production to logistics.

Issued May 2023