To ensure that the machine continues to provide top

quality performance, periodically clean the machine.

Warning

Do not use a flammable spray to clean the machine. If gas from the spray comes in contact with hot electrical components or the fusing unit inside the machine, fire or electrical shock may result.Caution

Wipe the parts with a clean, soft cloth.

If necessary, moisten the cloth with water or a small amount

of neutral detergent. After that, wipe with a clean dry cloth.

Examples

of lines in the image

Document

glass

.png)

Document

backplate sheet

.png)

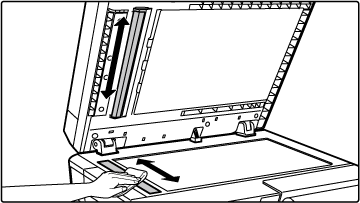

If black lines or white lines appear in images scanned

using the automatic document feeder, clean the scanning area(the thin

long glass next to the document glass).

To clean this part, use the glass cleaner that is stored in

the automatic document feeder. After using the glass cleaner, be

sure to return it to its storage position.

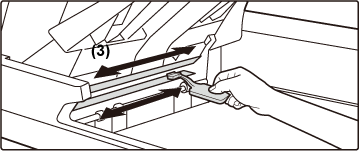

Open the automatic document feeder and remove the glass cleaner.

Clean the document scanning area on the document glass with the glass cleaner.

Clean the document scanning area in the automatic document feeder with the glass cleaner.

Replace the glass cleaner.

Open the automatic document feeder and clean the document scanning area on the document glass with the soft cloth.

When the laser unit inside the machine becomes

dirty, line patterns (colored lines) may form in the printed image.

Identifying

lines (colored lines) caused by a dirty laser unit

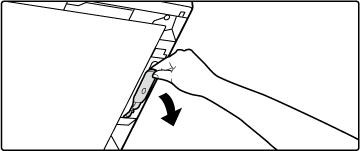

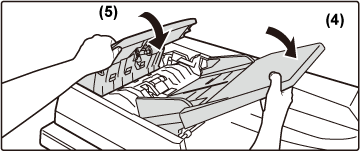

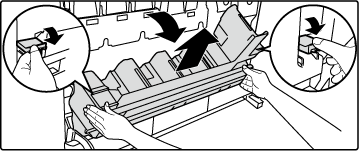

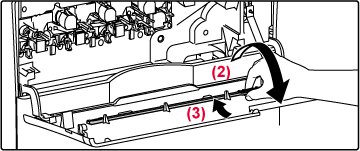

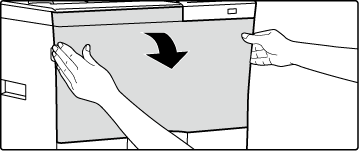

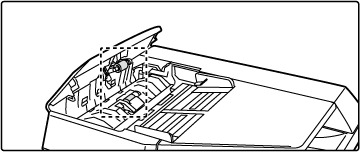

Open the front cover.

Open while pressing the convex parts on both sides.

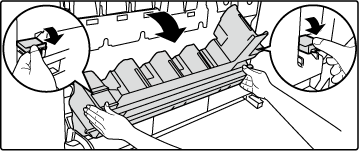

Remove the toner collection container.

Spread newspaper or something similar in advance where you will place the toner collection container.

Caution

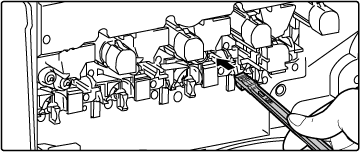

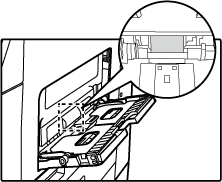

Take out the cleaning tool for the laser unit.

The cleaning tool is attached to the front cover.

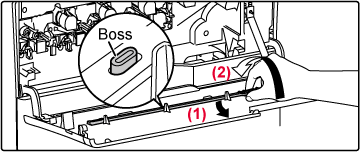

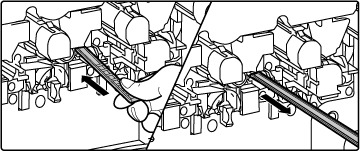

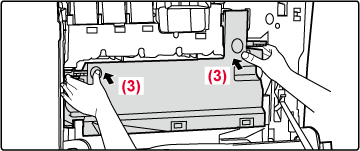

Clean the laser unit.

Caution

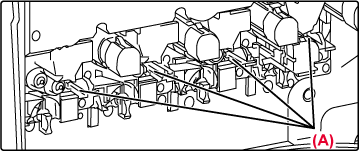

Do not touch the internal cords or connectors.Repeat steps 4 to clean all holes (4 holes) in the laser unit.

The laser unit is cleaned in four locations, including the location cleaned in step 4. Clean all holes.

Replace the cleaning tool.

Install a toner collection container.

Close the front cover.

Hold both sides and close.

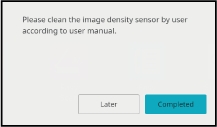

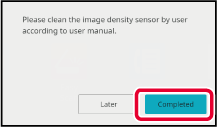

When the message "Please clean the image

density sensor by user according to user manual." appears, clean

the image density sensor using the following steps.

Caution

Tap the "Later" key to print, however, if you continue to use the printer with an image dirty density sensor, the printed image may be smudged.Turn off the machine.

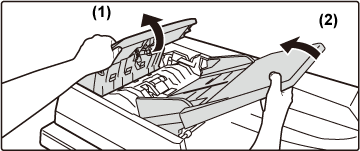

Press the [Power] button to turn off the machine. For details on how to turn off the power, see " TURNING OFF THE POWER."Open the front cover.

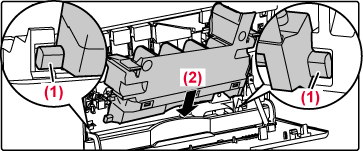

Open the front cover while pressing the convex parts on both sides.

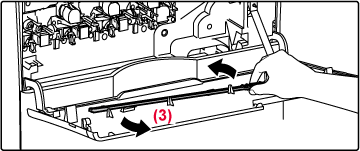

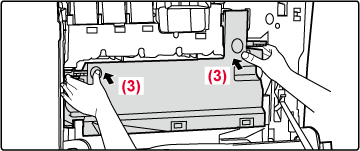

Tilt the toner collection container to the front.

Press the release buttons on the sides of the toner collection container, push the toner collection container down until the toner collection container stops.

Caution

Do not touch the internal cords or connectors.Push the toner collection container into the machine.

Push in until you hear a "click" sound indicating that the left and right locks are engaged.

Close the front cover.

Hold both sides and close.

Turn on the machine.

Press the [Power] button to turn on the machine. For details on how to turn on the power, see " TURNING ON THE POWER."Tap the [Completed] key.

Caution

If paper misfeeds frequently occur when

feeding envelopes or heavy paper through the bypass tray, wipe the

surface of the feed roller with a clean soft cloth moistened with

water or a neutral detergent.

If lines or other dirt appear on the scanned

original when the automatic document feeder is used, wipe the surface

of the roller with a clean soft cloth moistened with water.

BP-C535WR

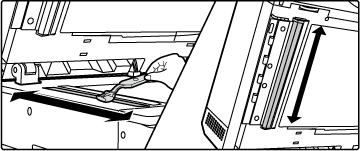

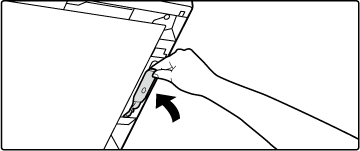

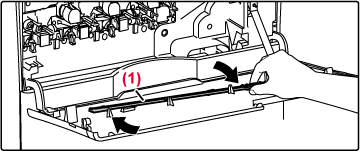

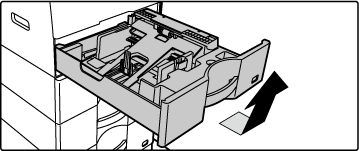

If the paper in tray 1 frequently misfeeds,

press down the center of the pressure plate until it locks, and

wipe the surface of the feed roller with a clean, soft cloth moistened

with water.

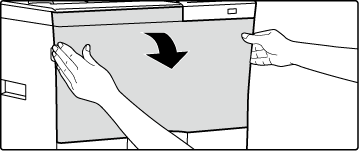

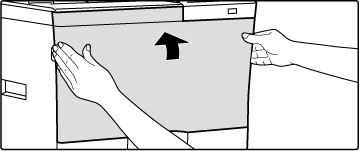

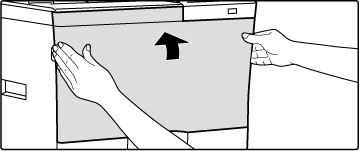

Pull out the paper tray 1.

Hold the tray with both hands and slowly pull out and up at a slight angle.

Clean the feed roller.

Version 03a / bpc545wd_usr_03a_us