Business Case Study

Tsumura & Co.

Appreciating customized support covering not only AGVs but also peripheral equipment.

Automation of manufacturing processes improves safety, quality, and productivity.

Pharmaceuticals

Improved productivity, Improved efficiency, Improved safety

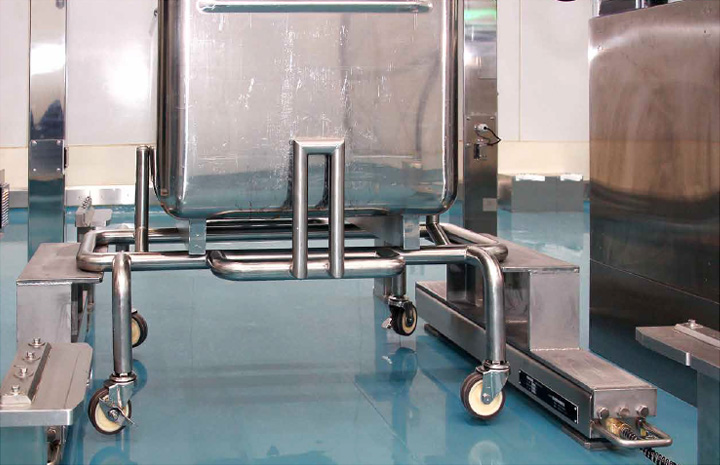

Automated guided vehicles (AGV), automated lid opening/closing devices

Dedicated container carriage, bar-type weigh scale, etc.

Installed in the granulation room of the extract granule manufacturing process at the Ibaraki Plant. Two lines and two systems have been in operation since March 2023 (four systems to be in operation by the end of 2023).

Minato-ku, Tokyo (head office)

Established in 1893. Tsumura & Co. is a leading kampo (traditional Japanese medicine) manufacturer. It manufactures and markets medical kampo products prescribed in many medical facilities as well as kampo products for general use.

Ibaraki Plant (site of this solution); Ami Town, Ibaraki Prefecture

We have been strengthening our ability to increase production in response to the growing demand for kampo products. We are expanding our plant and working to improve the production efficiency of our manufacturing processes with robots and AI. As part of this, we also wanted to automate the process of filling extract granules into containers and transporting them in our existing manufacturing building.

- We automated manufacturing processes in existing facilities with customized support that included not only AGVs but also peripheral equipment.

- The need to carry 175-kg containers has been eliminated, which has improved safety. And automated weighing prevents human error.

- We improved production efficiency by reducing manpower—the equivalent of two people per line—while raising production volume by 45 tons per year.

Need to address safety, burden reduction, and productivity improvement.

The granulation room handles one of the processes of manufacturing extract granules for kampo products. There, extract granules are repeatedly filled into special containers and carried out to the next process. Workers transport the containers, which can weigh as much as 175 kg when filled, on casters. This is physically demanding work and requires attention to safety. In addition, the process of changing and transporting the containers must be repeated every 20 minutes, making it a highly burdensome process. So we wanted to mechanize and automate it to improve production efficiency.

Tsumura & Co.

(left)Hiromichi Furuno

Section head

Manufacturing Section 5, First Manufacturing Department

Ibaraki Plant, Production Division

(right)Akira Takesako

Group leader

Technology Development Group 2, Technology Development Department

Production Technology Center, Production Division

Consideration given to the ease of cleaning required in a pharmaceuticals plant.

Sharp proposed and designed an automatic guided vehicle (AGV) and peripheral equipment capable of working with existing production facilities. We are highly appreciative of the fact that Sharp reproduced the granulation room’s special environment at its own facility and perfected a trackless AGV after running tests. Another important factor in our decision to choose Sharp was that it applied various ideas, such as using stainless steel processing, to make the AGVs and peripheral equipment easy to clean, something that is strictly required in a pharmaceutical plant.

The AGVs repeatedly change and automatically transport containers during the granule container-filling process.

Production volume increased by 45 tons per year as a result of better efficiency.

We automated the entire process of filling granules and changing/transporting containers on our two previously installed lines. This improved safety by eliminating the burden of carrying heavy containers. It also had benefits in terms of quality, as filling measurements are now linked to a bar-type weigh scale and automated, preventing human error. As for production efficiency, eliminating the task of container changing has resulted in manpower savings equivalent to two workers per line. And we can now operate without breaks, which we expect will increase our production volume by 45 tons per year.

Attention to preventing foreign matter contamination and ease of cleaning in automated lid opening/closing devices and container lids

Expectations for even further improvements in safety, quality, and productivity.

Amid growing demand for kampo products, we are working to improve our production efficiency by utilizing robots and AI for a new plant building. However, we have found that automating manufacturing processes in our existing plant building also has significant benefits. Our automation efforts have earned high acclaim, including an internal award for contributing to automation in the company. We expect to see even further improvements in safety, quality, and productivity in the future when we bring four systems on four lines into operation.

Better ease of cleaning by adopting a bar-type weigh scale for automatic weighing

Issued May 2023