◆Compact Low Floor Design Smart AGV

Complete freedom with a unit to suit the things being conveyed

Complete freedom with a unit to suit the things being conveyed

*Image

Example of a combination of TYPE A + cart unit

*Image

Example of a combination of TYPE A + a six-wheeled trolley towing unit

*Image

Example of a combination of TYPE C + basket truck towing unit

This function raises the hook mechanism after slipping under a basket truck or similar, senses the frame and then automatically fastens on.

This technology minimizes the impact of inertia and achieves stable traveling with software. This plays an active role in settings where tight turns are required.

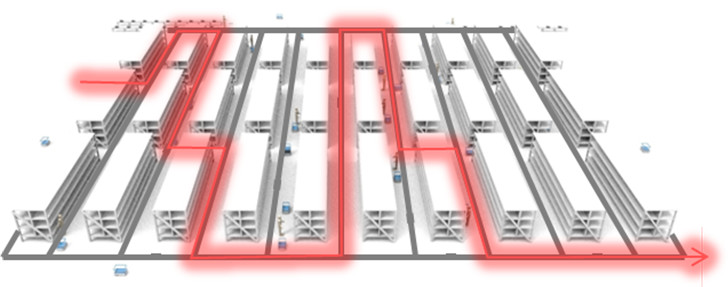

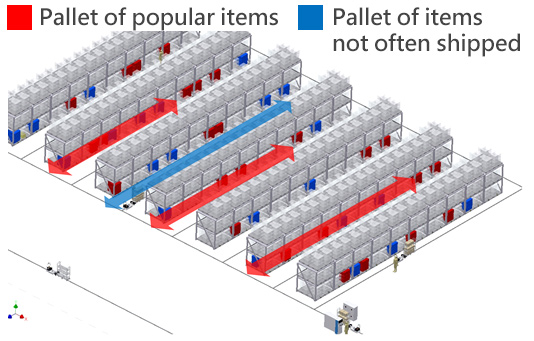

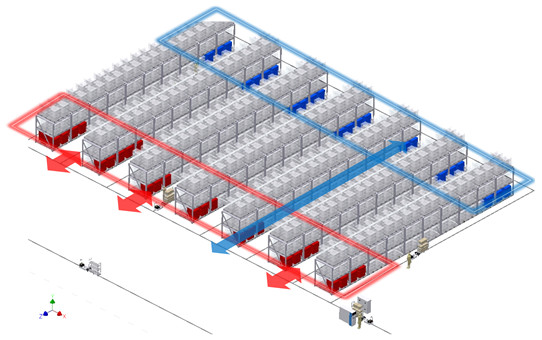

The system analyzes the location of popular items changing everyday based on the traveling log to recommend the optimal inventory position.

The conveyance distance is shortened and productivity is improved by arranging popular items that are often shipped near the branch lines.