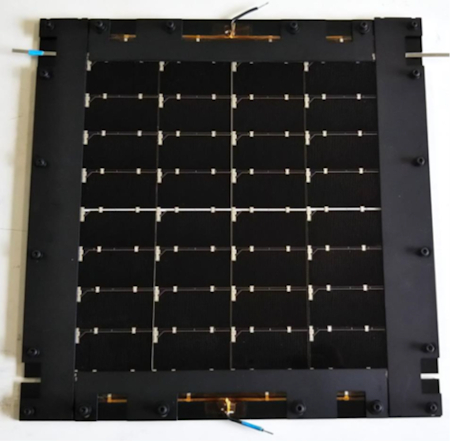

Tandem/silicon stacked solar cell module achieved a conversion efficiency of 33.66%

Sharp Corporation, working under the Research and Development Project for Mobile Solar Cells*3 sponsored by NEDO*4, has achieved the world's highest conversion efficiency of 33.66% in a stacked solar cell module that combines a tandem double-junction solar cell module*5 and a silicon solar cell module.

The conversion efficiency of this module breaks the world record of 32.65%, which our company achieved under a NEDO project in 2022. The prototype solar cell module has achieved high efficiency by efficiently converting light of various wavelengths into energy by a new structure which has compound two-junction solar cells on the top layer and silicon solar cells on the bottom layer. Additionally, the thickness of the tandem double-junction solar cells can be reduced to less than one-third that of conventional triple-junction solar cells, reducing material costs.

Going forward, Sharp will continue to conduct research and development to improve the efficiency and reduce the cost of solar photovoltaic modules, with a view to installing them in electric vehicles and mobile equipment as well as in the aerospace and aviation fields. Through this, we will contribute to reducing greenhouse gas emissions in the mobile field with the aim of achieving carbon neutrality by 2050.

This module will be featured at SHARP Tech-Day, our technology exhibition event to be held at the Tokyo Big Sight International Exhibition Center, East Hall 8 (3 Ariake, Koto-ku, Tokyo) from November 10 (Friday) to 12 (Sunday) of this year. The event will be open to the public.

For the information on SHARP Tech-Day and the registration for participation, please visit the special website at the link below.

*1 As of October 27, 2023, for solar cell modules at the research level (based on Sharp research).

*2 Figures confirmed in February 2023 by AIST (National Institute of Advanced Industrial Science and Technology) in Japan, one of the world’s official measurement agencies for solar cells [module area: 775 cm2, maximum output: 26.1W].

*3 Project objectives include: Development of technology to promote solar power generation as a primary power source; development of technology for creating new markets for photovoltaic power generation; and research and development of solar cells for mobile vehicles and equipment (development of ultra-high-efficiency module technology). Involved in joint research themes with the University of Tokyo and Toyota Institute of Technology. Project period: FY2020 to 2024.

*4 New Energy and Industrial Technology Development Organization (NEDO) is a Japanese national research and development agency that creates innovation by promoting technological development necessary to achieve a sustainable society.

*5 Double-junction structure with indium/gallium/phosphide as the top layer and gallium arsenide as the bottom layer.

■ Development background

In the transportation industry, which relies on fossil fuels for most of its energy needs, the movement to introduce electric vehicles is accelerating as part of its efforts to reduce CO2 emissions and combat air pollution. As a result, it is anticipated that the supply of electricity will be increasingly derived from renewable energy with the aim of maximizing these effects. In addition, installing solar cells on mobile equipment such as electric vehicles will make it possible to supply electricity directly from renewable energy sources which is expected to improve user convenience by reducing fuel costs and the number of charging cycles.

Based on this background, Sharp is developing technology for solar cell modules that can be mounted on mobile equipment that feature high efficiency and low cost and which will be widely installed on regular electric vehicles and mobile units as well as for use in the space and aviation fields. Under this project, we have achieved the world’s highest conversion efficiency of 33.66%.

■ Results

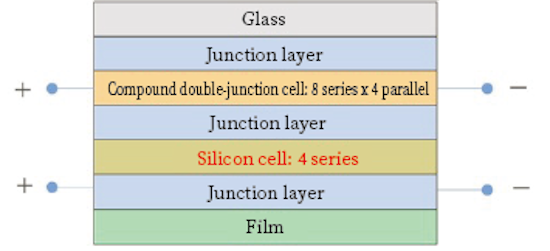

1.Development of a tandem/silicon stacked solar cell module Until now, the module’s base has been a compound triple-junction solar cell that stacks three light absorption layers with indium/gallium/arsenide as the bottom layer, but we changed to a new structure with a double-step junction of indium/gallium/phosphorous and gallium arsenide as the top layer and silicon on the bottom layer. The tandem double-junction cell in the top layer has been designed to achieve high efficiency even in a thin layer and improve light transmittance to the bottom layer, making it possible to efficiently convert light of a variety of wavelengths into energy*6. In addition, the thickness of the tandem double-junction cells can be reduced to less than one-third that of conventional triple-junction cells, which is expected to reduce material costs.

Solar cell module structure

*6 Collaborative development with the University of Tokyo: Improving efficiency with a thin layer of tandem double-junction solar cells (top layer)

Collaborative development with Toyota Institute of Technology: Improving the efficiency of silicon solar cells (bottom layer)

2.Achieving the world's highest conversion efficiency

In April 2013, we achieved a conversion efficiency of 37.9% for a small-sized (area: 1.047 cm2) compound three-junction solar cell. And in 2022, we modified the structure to one in which the cell is sandwiched between thin films. By improving the average conversion efficiency of the cells and improving the cell packing density, we achieved a conversion efficiency of 32.65% in a lightweight and flexible practical-sized module (area: 965 cm2).

This time, by changing the structure to a stacked solar cell module that combines a tandem double-junction solar cell module and a silicon solar cell module, we were able to improve the conversion efficiency to 33.66% in a practical size module (775 cm2 area).

Choose

Choose