Quality / Customer Satisfaction

Ensuring Quality and Safety

| Fiscal 2022 Objectives | Fiscal 2022 Achievements | Self-Evaluation | Priority Objectives for Fiscal 2023 |

|---|---|---|---|

|

|

★★ |

|

- Self-evaluation: ★★★ Achieved more than targeted / ★★ Achieved as targeted / ★ Achieved to some extent

Basic Stance and Vision on Quality

To gain customer trust and improve customer satisfaction, based on its Quality Philosophy and Quality Slogan, the Sharp Group constantly strives to respond to customer needs and demands by providing products and services that are safe, high quality, and reliable.

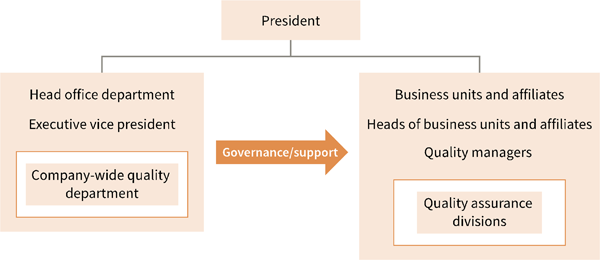

Quality Assurance System

Under the supervision of the executive vice president, the company-wide quality department leads governance and supports related efforts for the entire Sharp Group. Under this system, each business unit and affiliate autonomously conducts its business.

Sharp Group’s Quality Assurance System

Quality Management System

To enable it to conduct a variety of quality assurance activities in all stages of the manufacturing cycle, including planning, design, procurement, production, assessment, and after-sales, the Sharp Group established the Sharp Corporation Standard based on the ISO 9001 international quality management standard. Stipulating systems and methods necessary for quality assurance, the Sharp Corporation Standard is strictly adhered to by all Sharp sites in Japan and other countries, and by consolidated subsidiaries carrying out design, production, and sales.

Through ongoing revision and implementation of the standard, all employees—in product planning, design, production, sales, and after-sales service—know exactly the level of quality they should be guaranteeing customers in Sharp’s continuous efforts to improve quality.

As of April 30, 2023, 37 of 38 sites are certified for ISO 9001. The certification rate is 97.4%.

Quality Assurance Activities in the Product-Making Cycle

Quality Policy

In line with the Quality Policy stipulated in Sharp Corporation’s company rules (Quality Assurance Basic Rules), the Sharp Group makes and implements quality plans aimed at achieving the quality targets it has set.

Quality Policy

Provide high quality and attractive products that customers can continuously use them with safety and satisfactory.

- Observe laws and regulations and place top priority on safety and reliability.

- Pursue convenience and comfort from usability.

- Squarely face with voice of the customer and reflect it in products.

Efforts to Improve Quality

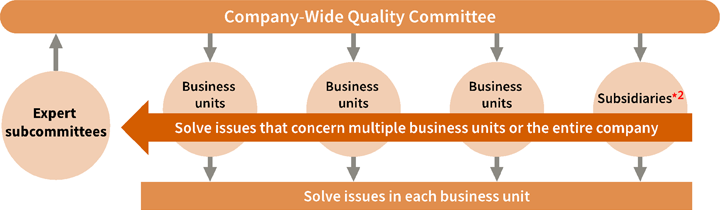

As a way to advance quality technologies, the Sharp Group has established the Company-Wide Quality Committee, which is chaired by an executive vice president and includes the general managers of each business unit and the presidents of affiliated companies. The Committee convenes to take up such matters as company-wide research and improvement efforts to assure quality in new business areas, such as 8K+5G, AIoT*1, and digital healthcare. It also determines response policies for immediate quality issues and sets fiscal-year targets related to quality.

In addition, a Quality Strategy Promotion Committee comprising quality managers from the various business units is convened under the auspices of the Company-Wide Quality Committee to serve as a forum for discussing specific quality measures. Issues that span the entire Sharp Group or multiple business units are taken up by topic-specific expert subcommittees, made up of experts from the various business units, which work to find prompt solutions.

Company-Wide Quality Committee System

- *1 AIoT is a word coined by Sharp, combining the words AI (artificial intelligence) and IoT (Internet of things). AIoT is a vision of how products and services will connect to artificial intelligence via the cloud and become a people-oriented existence. AIoT is a registered trademark of Sharp.

- *2 Subsidiaries of Sharp business unit status.

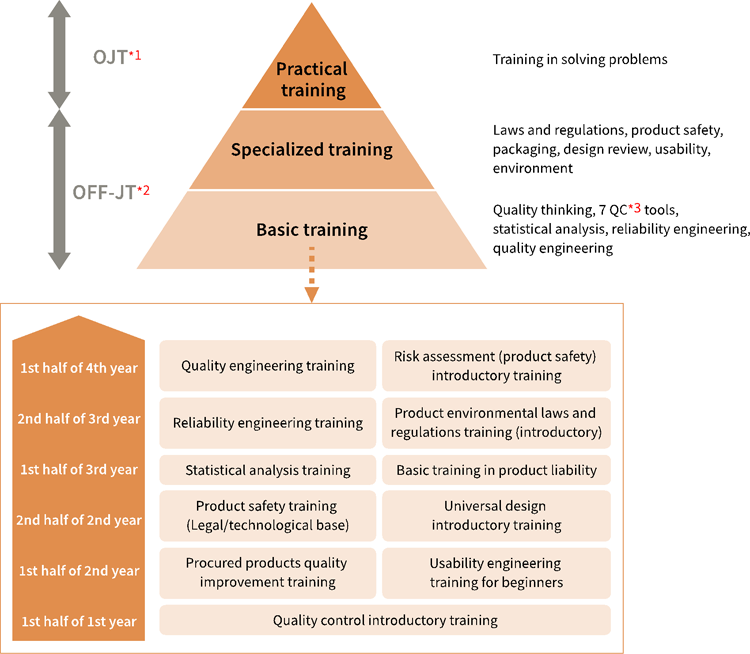

Fostering Quality Experts

Fostering Quality Experts

Based on its Quality Philosophy, Sharp works to foster quality thinking and boost quality-related techniques by carrying out systematic quality-related education with the aim of making products that customers can use with safety and peace of mind.

In particular, the company is stepping up basic training through programs that allow young employees (in their first four years with the company) to gradually acquire quality-related techniques.

QC Practical Training System

- *1 OJT: On the job training.

- *2 OFF-JT: Off the job training.

- *3 QC: Quality control.

Sharp implements training in a variety of forms and formats adapted for different educational objectives. First, there are e-learning programs and videoconference classes, which are used to help maximize learning efficiency. There are also group training courses to improve practical skills, which are carried out at the different business units and affiliated companies. In fiscal 2022, there were 38 courses in quality training, with a total of 8,411 participants.

Fiscal 2022 Training Courses and Number of Participants

| Training form | No. of courses | No. of participants |

|---|---|---|

| E-learning | 25 | 7,427 |

| Group training | 13 | 984 |

| Total | 38 | 8,411 |

Ensuring Product Safety

Sharp Voluntary Product Safety Action Policy

Keenly aware that product safety assurance is the most important aspect of a company’s business and one of its social responsibilities, Sharp strives to provide customers with safety and peace of mind. It does this by prioritizing the safety of the products it manufactures and sells and by making safety-related information public. To this end, the company has formulated voluntary action guidelines on product safety in efforts to earn an even higher level of trust from society.

Efforts to Ensure Product Safety

Sharp strives to ensure its products are safe and to constantly raise levels of safety. Besides abiding by laws and regulations of countries and obtaining safety certifications through activities such as factory audits by third parties, the company utilizes its own risk-assessment-based safety standards. To ensure safety even in cases where unforeseen defects arise, these in-house safety standards stipulate items like flame-retardant construction and testing for abnormal conditions. These standards are revised as needed and are taught to all relevant employees in design, quality, and other divisions so that they are understood and followed thoroughly.

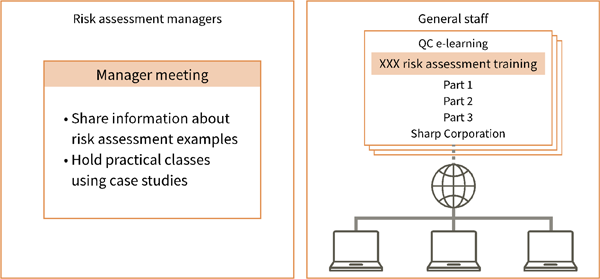

Since fiscal 2020, Sharp has been striving to expand the practice of risk assessment related to product safety. Besides providing skills improvement courses via e-learning, we have been strengthening our risk assessment system by appointing a risk assessment manager in each business unit with the goal of developing increasingly safer products.

Sharp will continue to step up efforts to promptly respond to social changes and legal revisions regarding product safety so that customers can use Sharp products with peace of mind.

Initiatives to Strengthen Risk Assessment

Information Disclosure and Response When Problems Occur

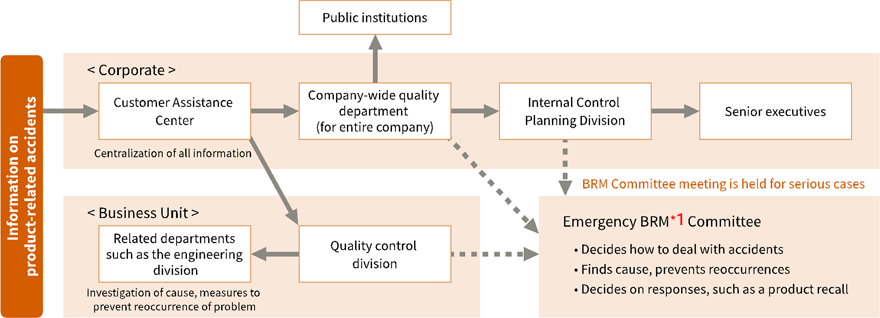

If an accident caused by a Sharp product occurs on the market, the company immediately gathers information on the accident and analyzes it to determine the cause. If it is determined that there is a risk of harm or damage to the customer, information is promptly disclosed via media such as newspapers and the Sharp website, and all appropriate measures are taken to ensure the safety of customers.

Flow for Dealing with Product-related Accidents

- *1 BRM: business risk management.

For major product-related accidents stipulated in the Consumer Product Safety Act, the Sharp website has a list of information on major product-related accidents for which the cause is thought to be the product itself. There are 5 such cases.*2

- *2 Number in fiscal 2022 (as of March 31, 2023).

Product Security Policy and Efforts

Products connected to networks are exposed to growing risks as information technology advances and the value of information they handle increases. They are at a risk of cyber-attack taking advantage of their vulnerabilities, which can result in information leakage or a hijacking of the device being hacked. Security measures once considered adequate are now seen as insufficient, owing to technological advances and other factors. Around the world, there is an urgent and growing need to improve legislation on product security.

Such a situation has been prompting Sharp to act to ensure that customers can use its products without worries. We have established teams and reporting lines dedicated to enhancing product security, along with the rules to be followed at the stages of planning, developing, operating, and maintaining products. We also gather vulnerability information and share it internally based on a vulnerability information disclosure policy. And, we thoroughly train employees to ensure that our products continue to have a high level of security.

We are expecting a future in which standalone systems are interconnected with one another, perhaps creating added vulnerabilities. To prepare for such a future, the Sharp Group has adopted security by design, a concept that intends to build in security from early stages before design. This approach to product development is shared throughout the organization.

Making Easier-to-Use Products

Practicing User-Centered Design

Sharp practices user-centered design (UCD) in order to provide products that customers find easier to use.

UCD is a concept—as outlined in the international ISO 9241-210 standard—to provide products and services that satisfy customers by seeing things from their perspective, understanding their needs, and reflecting them in product design. Sharp has its own UCD Basic Policy and the Eight Principles of UCD based on this concept and shares them across the Sharp Group. Sharp investigates customers’ latent dissatisfaction and needs as part of its product development process and reflects those findings in the specifications and design of its products. By repeatedly going through evaluations and improvements, Sharp is bringing forth products and services that customers find easy to use and attractive.

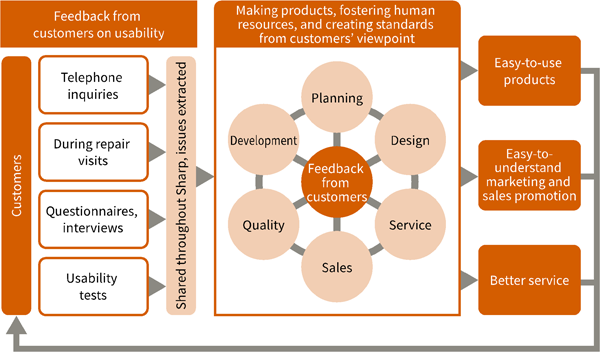

Flow of Customer-Oriented Manufacturing

Customer-Oriented Manufacturing

In user-centered design (UCD), Sharp collects customer feedback on ease of use through various methods and applies it to product design.

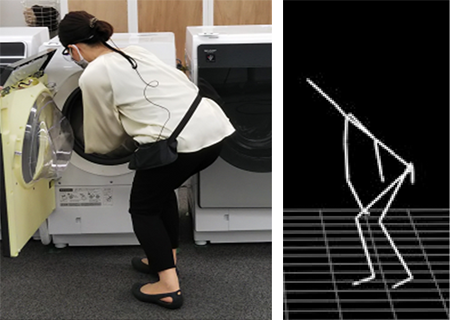

Through usability tests*, questionnaires, interviews, and opinions gathered from customers during Customer Assistance Center phone calls and repair visits, anonymous information from customers is compiled and shared among Sharp development personnel, who put it to use in new product design.

For in-person information gathering, such as usability tests, conducted during the Covid-19 pandemic, strict measures were taken to prevent infection. When necessary, these activities were continued using online means.

- * Tests that involve observing how people use Sharp products and services.

Behavior analysis for a front-loading washer/dryer

Usability test for a TV

Comments from Participants in Usability Tests

- It was very helpful to get user feedback from the tests, because they pointed out issues the developers were not aware of. (Sharp product planning staff member)

- Being able to observe users and hear from them directly was extremely beneficial. It provided us with new insights and new issues to focus on. (Sharp design staff member)

- If it helps even a little bit, I would be happy to participate again. (Sharp employee in her 50s)

Efforts in Accessibility and Universal Design

In line with the UCD Basic Policy, Sharp also pursues accessibility and universal design (UD). These efforts are rooted in a philosophy of building products, information, and environments so that they can be used by many more customers—regardless of things like nationality, age, gender, or disability. Sharp strives to develop products and services that can be used comfortably by as many people as possible by conducting evaluations and surveys of mainly home appliances and digital multifunction printers (MFPs).

As of May 2023, Sharp’s efforts have produced 18 models of Sharp home appliance products that support the UD considerations listed on the website of the Association for Electric Home Appliances in Japan.

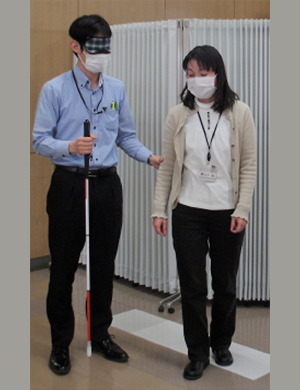

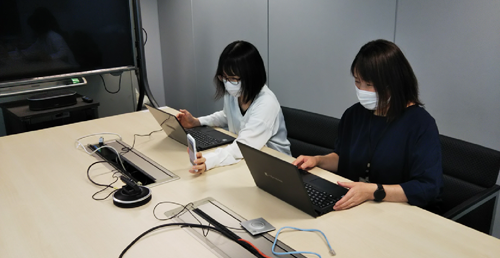

To continue the aforementioned activities company-wide, Sharp works to foster human resources through training. Major education activities include introduction to universal design (e-learning) to impart the understanding and acquisition of basic UD knowledge, UD experience learning, in which employees see firsthand what it’s like to be physically disabled so that they can know how to make products more accessible, and a usability training system for specialized education.

During the Covid-19 pandemic, UD experience learning group training was temporarily suspended and a web conferencing system was utilized to provide online classes. Both group training and online classes have their merits and will be used where they are most appropriate moving forward.

Evaluating the usability of a multifunction copier

for the vision-impaired

(a kiosk terminal to provide government services)

Evaluating the accessibility of

a front-loading washer/dryer

(for wheelchair users)

Walking as a vision-impaired person

in UD experience learning

Online UD experience learning

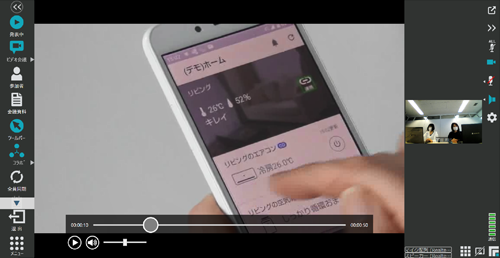

Computer screen image for online UD experience learning

Efforts to Ensure Accessibility

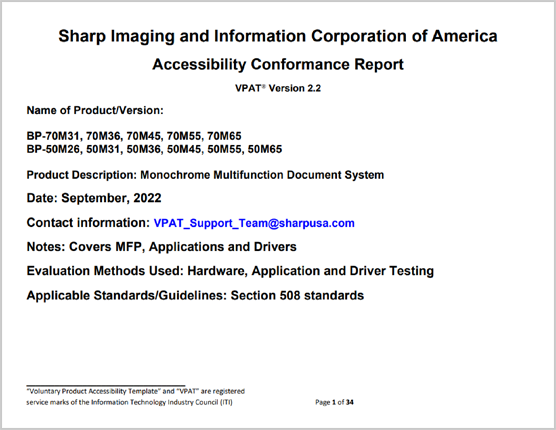

Accessibility is the concept of making products and services so that they can easily be used by people who are in some way limited in their physical functions; for example, senior citizens and the physically disabled. Under U.S. federal law*1, federal agencies purchasing equipment and services are obligated to choose those that are accessible to everyone, including the physically disabled. For Sharp digital MFPs and other products, assessment results of accessibility standards stipulated by federal law are compiled on a product evaluation sheet (VPAT*2), which is disclosed on the website of Sharp Electronics Corporation (SEC), Sharp’s U.S. sales company.

Example of VPAT for a digital MFP

- *1 Section 508 of the Rehabilitation Act.

- *2 VPAT: Voluntary Product Accessibility Template. A table containing information regarding how a particular product or service conforms with Section 508 of the U.S. Rehabilitation Act.

Healsio Hotcook Development Team Wins METI Minister’s Prize at the 9th Monodzukuri Nippon Grand Awards

The development team of the Healsio Hotcook waterless automatic cooker won the Minister of Economy, Trade and Industry Prize, the highest ranked award in the “Connected Industries—Outstanding Collaboration” category of the 9th Monodzukuri Nippon Grand Awards.

This awards program recognizes particularly outstanding individuals from various generations involved in monodzukuri, or manufacturing, including mid-career personnel who play a central role in production sites, skilled personnel who have supported traditional and cultural skills, and the younger generations who will lead the future.

The Healsio Hotcook is a cooking appliance that can be used simply by adding ingredients and seasonings and pressing a button. By automating most of the cooking process, this product provides users with more physical and mental free time. In addition, the device’s potential for new business development to support diversifying lifestyles, such as a cloud-based recipe service and interconnectivity with other Sharp kitchen appliances, were well received and contributed to its selection for this award.

Monodzukuri Nippon Grand Awards logo

Healsio Hotcook waterless automatic cookers KN-HW24G-R (red) and KN-HW24G-W (white)

Customer Satisfaction

Aiming for Customer-Oriented Services

Customer Assistance Center (Japan)

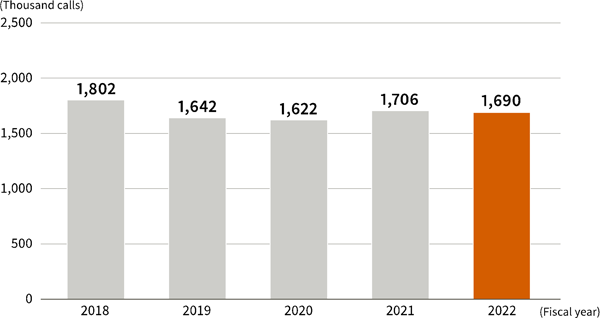

The Customer Assistance Center responds to a wide range of product-related inquiries from customers—approximately 1.7 million annually—so that Sharp can provide customer-oriented support. To this end, the center meets periodically with product development departments to give them feedback in the form of customer inquiries, which leads to the development of improved and new products.

We are also enhancing the customer support website to make it more user-friendly and to help customers troubleshoot issues by themselves. In October 2018, we started providing chatbot-based automated responses. In November 2020, we started an operator chat service for customers who were unable to resolve their issues using the chatbot. In this way, we have been expanding support channels in line with the spread of smartphones.

Sharp is striving to respond to diversifying customer needs and achieve its goal of always serving in a customer-oriented manner.

Number of Calls Received from Customers in Japan

Reliable Operation of Customer Support

The Customer Assistance Center must be able to provide customer support even in challenging times, such as during natural disasters such as earthquakes and typhoons.

Our business continuity plan (BCP) ensures the continued operation of our customer support services even in emergency situations. Our support offices are distributed across multiple locations and are connected through a system that makes them ready to complement one another.

Improving Response to Customers

As the face of Sharp, customer consultants study products and learn how to interact properly with customers before they start their jobs. Even after they have begun their jobs, consultants periodically undergo training and study sessions to boost their skills.

The department that runs the Customer Assistance Center maintains and improves person-to-person dealings with customers by having employees take periodic qualification upgrading tests to brush up their skills. It also uses text messaging to conduct questionnaires that will help better respond to customer wishes and improve the support site.

Upskilling Customer Consultants

| Personnel | Implementation |

|---|---|

| Customer consultants (trainees) |

Acquire basics in manners, product knowledge, and consumer-related laws and regulations |

| Test ability to serve as customer consultants | |

| Customer consultants (after starting their jobs) |

Improve customer consultant skills through periodic training and study sessions |

| Determine how well customer consultants have acquired skills by having them periodically take qualification upgrading tests | |

| Supervisors | Ensure person is fit to be a supervisor |

| Improve supervisor skills through periodic training and study sessions | |

| Determine how well supervisors have acquired skills by having them periodically take qualification upgrading tests |

Enhancing Customer Satisfaction through After-Sales Service

| Fiscal 2022 Objectives | Fiscal 2022 Achievements | Self-Evaluation | Priority Objectives for Fiscal 2023 |

|---|---|---|---|

|

|

★★★ |

|

- Self-evaluation: ★★★ Achieved more than targeted / ★★ Achieved as targeted / ★ Achieved to some extent

Basic Stance on Customer Satisfaction

Providing Products and Services That Offer Peace of Mind and Satisfaction

Sharp always thinks from the customer’s point of view and, as a rule, develops and provides products and services with the customer in mind. To ensure that customers can continue to use Sharp products for many years with peace of mind, Sharp strives to improve its products and its sales and after-sales services by reflecting the opinions of customers.

Sharp will continue to pursue customer satisfaction (CS) so that customers choose Sharp now, next time, and every time.

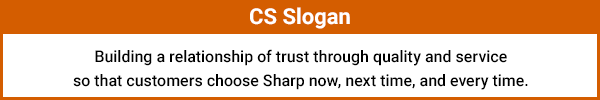

After-Sales Service System

Sharp has an after-sales service system that can handle all kinds of customer inquiries, whether it’s instructing them how to use products or repairing products that are not working properly.

Centered on Sharp Corporation’s Customer Assistance Center and after-sales service departments at Sharp sales companies, the entire Sharp Group worldwide collaborates to provide high-quality, fast, accurate, and friendly service that truly satisfies customers.

Flowchart

Repair and Servicing System (in Japan)

Repair of Sharp products in Japan is carried out by Sharp Marketing Japan Corporation, Customer Service Company. The entire company works together with a user-oriented mindset to satisfy customers and realize its slogan: “Looking customer smile is my pleasure.”

Service engineers, who work out of more than 90 service bases*1 all over Japan and are familiar with local customers, provide repair service that truly satisfies customers. Service inquiries are accepted every day of the year*2. The company puts special effort into prompt response to problems with home appliances that are indispensable to daily life, such as washing machines, refrigerators, and air conditioners.

- *1 As of April 2023.

- *2 Business days vary from region to region.

Service That Brings Smiles Back to Customers

Provide Speed, Reliability, and Peace of Mind

I’m a service engineer at Sharp Marketing Japan Corporation, Customer Service Company. As such, I strive every day to improve my aftersales skills to make customers happy.

With people’s increasingly diverse lifestyles and growing concern about zero waste in society, I am keenly aware that aftersales service is more important than ever. That’s why we strive for customers’ peace of mind by offering prompt and reliable repairs to quickly resolve any inconvenience. After repairs are completed, I make it a point to leave customers with a smile by explaining what we have done in plain, simple language and giving advice on future product use.

I’ll keep improving myself as a service engineer by boosting my technical and customer satisfaction skills. My goal is to provide speed, reliability, and peace of mind to customers so that I can change their temporary negative experience to a positive one and make them want to buy Sharp next time too.

Hideto Wada

South Tokyo Service Center, Customer Service Company,

Sharp Marketing Japan Corporation

Customer Questionnaire

At Sharp, all customers who are visited by service engineers are asked to answer a questionnaire covering the entire service process, from initial inquiry and appointment to product repair. More than 100,000 customer opinions are received annually via this questionnaire.

To improve convenience for customers and to speed up response, the traditionally postcard-based questionnaire has also been available on the Sharp website since fiscal 2017. Starting in fiscal 2022, the survey is completely web-based.

Sharp will continue to pass on customers’ valuable opinions to relevant company departments, closely analyze problems, and use the information gathered to improve service mechanisms and manufacturing

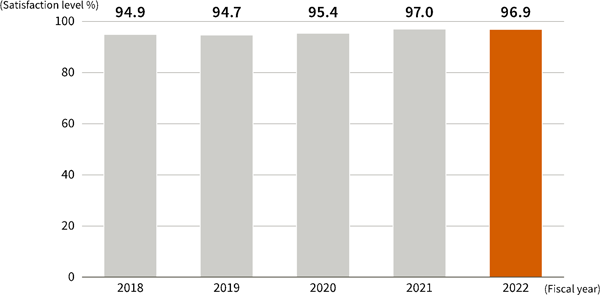

Percentage of Customers Giving Satisfactory and High Marks to Service Engineers (postcard and online surveys)

Reflecting on Customer Questionnaires (Japan)

Customer Service (CS) Awareness Meetings

At service bases in Japan, we work to improve CS skills through training sessions (CS awareness meetings) that involve reflecting on the feedback and suggestions provided via customer questionnaires.

CS awareness meeting

Despite the fact that the work required disassembling so many parts, the service engineer was skillful and did a great job. He even removed a large amount of dust from the washing machine. Even after he left, the area around the washing machine was completely free of any debris or dirt. I was extremely satisfied. Thank you very much. (Woman in her 40s)

The service engineer was extremely polite. He also told me the product’s features and explained each. I decided to go with mostly Sharp products after my last move, and because of the great repair service that I received, I intend to stick with Sharp products in the future. The service engineer was a great help. Thank you very much! (Man in his 40s)

I was thinking of going with a different manufacturer, but the service staff made such a good impression that I decided, if they were so good at figuring out the cause of problems and providing solid after-sales service, I would continue using Sharp products. (Woman in her 30s)