Climate Change

Sharp’s Stance on Climate Change

Medium-term Environmental Goals

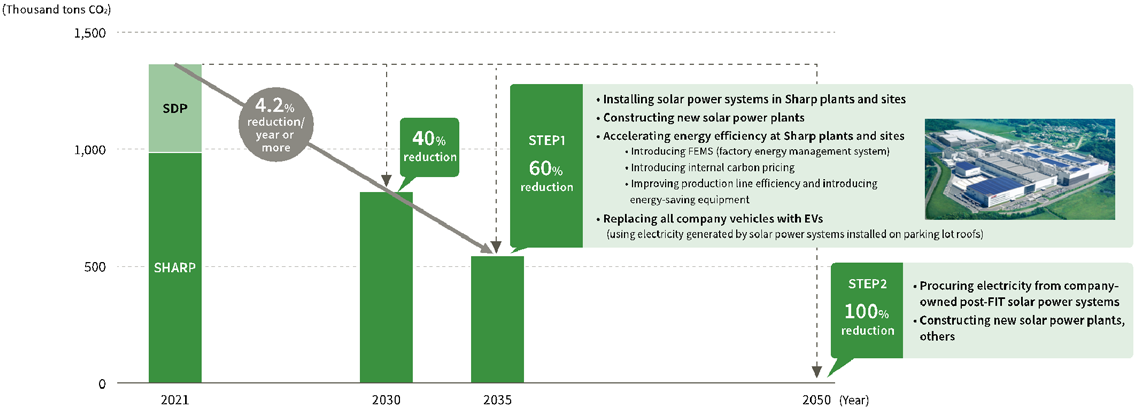

Climate change is the most pressing and important issue currently facing humanity. It is driving an increase in natural disaster severity that significantly impacts, both directly and indirectly, not only our daily life but business as well. Sharp recognizes that climate change is a material management issue and is working to address this issue through its long-term environmental vision, SHARP Eco Vision 2050, which was created in 2019 and which encompasses a goal to “Achieve net zero CO2 emissions in Sharp business activities.” To achieve our long-term environmental vision, we have also set new medium-term environmental goals—a 40% reduction in CO2 emissions by 2030 and a 60% reduction by 2035*.

Going forward, Sharp will continue to steadily reduce CO2 emissions by installing solar power systems in our plants and other sites, saving energy, building new solar power plants, and converting the company fleet to electric vehicles (EVs).

- * Compared with fiscal 2021. Includes emissions from fiscal 2021 onwards from Sakai Display Products Corporation, which became a wholly owned subsidiary of Sharp Corporation in June 2022.

Medium-term Environmental Goals for Achieving Net Zero CO2 Emissions from Corporate Activities

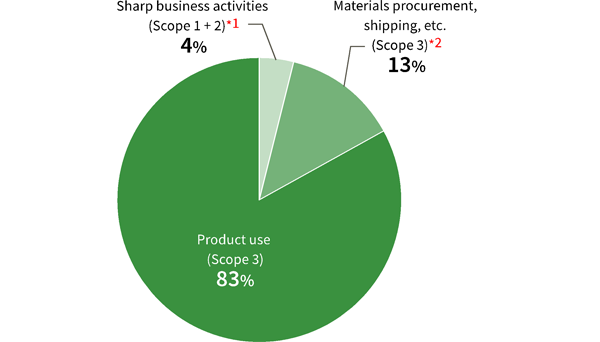

Reducing Environmental Impact Associated with Product Usage

When greenhouse gas emissions for the entire Sharp value chain are calculated and analyzed, the results show that more than 80% of emissions are associated with the use of sold products. Based on this fact, Sharp has identified reducing environmental impact associated with product usage by customers (i.e., improving product energy efficiency) and Sharp business activities (i.e., manufacturing) as material issues in addressing climate change.

Breakdown for Sharp Greenhouse Gas Emissions (Fiscal 2022)

- *1 Direct GHG emissions from business activities.

- *2 Indirect GHG emissions from energy usage in business activities.

Ways to reduce GHG emissions by creating environmentally conscious products

- Quantifying and analyzing GHG emissions throughout the product life cycle

- Incorporating AIoT*3 devices and cloud technology to reduce GHG emissions during product use

- Reducing GHG emissions through the provision of conducive products and services (e.g., solar power systems and storage batteries)

- *3 AIoT is a word coined by Sharp, combining the words AI (artificial intelligence) and IoT (Internet of things). AIoT is a vision of how products and services will connect to artificial intelligence via the cloud and become a people-oriented existence. AIoT is a registered trademark of Sharp.

Participation in Climate Crisis Initiatives and Other Efforts

Sharp participates in the Science Based Targets initiative (SBTi)*4, which is focused on pursuing action that will achieve real and reliable results in the fight against climate change. Sharp has been certified for SBT WB2°C*5 (well below 2°C) and is now preparing to get certified for the 1.5°C target*6. This will align the company with medium-term environmental goals we set in June 2022. We also aim to use 100% renewable energy in business activities and are preparing to join RE100, a global initiative for 100% renewable electricity.

In Japan, Sharp participates in the Liaison Group of Japanese Electrical and Electronics Industries for Global Warming Prevention*7, which is a group focused on strengthening industry-wide decarbonization action. The members of this group share information about the latest energy-saving initiatives being implemented in factories, and they engage in discussion related to policy recommendations. Sharp also participates in the Japanese Ministry of Economy, Trade and Industry’s GX League*8, which fully launched in fiscal 2023. Through this, Sharp is ramping up its efforts to contribute to global carbon neutrality.

Progress towards Science Based Targets (WB2°C Target)

| Target | Fiscal 2022 Results | Base Year Comparison | |

|---|---|---|---|

| Scope 1 + 2 | By fiscal 2031, reduce GHG emissions by 33% compared with fiscal 2018 | 1,125 thousand tons CO2 | 4% increase |

| Scope 3 (Category 11) | By fiscal 2031, reduce GHG emissions by 33% compared with fiscal 2018 | 25,800 thousand tons CO2 | 6% reduction |

- *4 This climate change-related initiative is a collaborative effort of the United Nations Global Compact (UNGC), the CDP, World Resources Institute (WRI), and the World Wide Fund for Nature (WWF). The SBTi promotes the establishment of science-based GHG emissions reduction targets in conformance with the Paris Agreement.

- *5 A target of keeping the increase in global average temperatures to well below 2°C above pre-industrial levels.

- *6 A target of limiting the increase in global average temperatures to 1.5°C above pre-industrial levels.

- *7 This group comprises companies from electrical and electronics industry associations in Japan, such as the Japan Electrical Manufacturers’ Association (JEMA) and the Japan Electronics and Information Technology Industries Association (JEITA). The Liaison Group undertakes industry-wide efforts aimed at preventing global warming—for example, proposing action plans to achieve carbon neutrality.

- *8 GX stands for ‘green transformation’—an initiative to transform society into being carbon neutral by 2050. The GX League is a forum where companies pursuing sustainable growth collaborate with other companies, government, and academic organizations that share the same GX goals.

TCFD-based Information Disclosure

Action on the TCFD Recommendations

The Task Force on Climate-related Financial Disclosures (TCFD) was established by the Financial Stability Board (FSB), an organization promoting international financial stability. In 2017 the TCFD released recommendations for companies to disclose information on the risks and opportunities of climate change. Sharp has declared support for the TCFD recommendations and is expanding disclosure of climate-related information in accordance with the framework set by the TCFD.

1. Governance

Climate-related issues are monitored and countermeasures supervised by the President & CEO, who chairs the Sustainability Committee. The committee includes senior executives and members from head office departments, business units, and subsidiaries. The committee works to thoroughly implement policies and visions related to aspects of ESG such as climate change; it deliberates on and promotes active measures; and it shares the latest trends on societal issues.

Through monitoring and review by management at committee meetings, Sharp continuously strengthens climate change action to play a part in making society sustainable.

2. Strategy

Sharp sees climate change as both a risk and an opportunity in the medium to long term. We are studying strategies and learning about organizational resilience in the context of climate change-related risks and opportunities. To understand long-term impacts up to 2050, we analyzed climate change scenarios outlined by the International Energy Agency (IEA) and the Intergovernmental Panel on Climate Change (IPCC) (1.5°C scenario*1 and 4°C scenario*2). The following table provides detailed information about those risks and opportunities, along with a summary of associated measures.

3. Risk Management

Sharp identifies and assesses climate-related risks in accordance with the Rules of Business Risk Management, in which the basic approach to risk management has been established. Specifically, Sharp identifies climate-related risks that are highly likely to occur based on its analysis of climate scenarios forecast for the future. Sharp reports its findings as necessary to senior executives and the Internal Control Planning Division, which serves as the risk management secretariat. It also facilitates necessary improvement measures in partnership with involved departments.

4. Metrics and Targets

Sharp’s long-term environmental vision, SHARP Eco Vision 2050, aims to achieve net zero CO2 emissions from business activities by 2050. To reach this target, Sharp has set a medium-term environmental goal of reducing CO2 emissions by 60%*3 by 2035. This goal, which is based on the SBT 1.5°C target, reflects our aim of reducing annual CO2 emissions by at least 4.2%.

- *1 IEA Net Zero Emissions by 2050 Scenario; SSP1-1.9 scenario from the IPCC 6th Assessment Report (AR6).

- *2 RCP 8.5 scenario from the IPCC 5th Assessment Report (AR5).

- *3 Includes emissions from fiscal 2021 from Sakai Display Products Corporation, which became a wholly owned subsidiary of Sharp Corporation in June 2022.

Progress towards Reducing GHG Emissions (Fiscal 2022 Results)

| Base Year (fiscal 2021 results*3) |

Fiscal 2035 Target (60% reduction compared with fiscal 2021) |

Fiscal 2022 Results | Base Year Comparison |

|---|---|---|---|

| 1,365 thousand tons CO2 | 546 thousand tons CO2 | 1,125 thousand tons CO2 | 17.6% reduction |

Business Risks and Opportunities; Sharp’s Response

| Scenario | Factors | Changes | Impacts on Sharp | Risk or Opportunity | Degree of Impact | Time Until Impact Becomes Apparent* | Sharp’s Response |

|---|---|---|---|---|---|---|---|

| 1.5℃ | Introduction of carbon pricing | Increased raw material procurement costs | Costs passed on to purchase prices due to carbon tax levied on Sharp-purchased products | Risk | Large | Short term |

|

| Increased direct operational costs | Increased payment costs due to carbon tax levied in line with Sharp’s Scope 1 and 2 emissions | Risk | Large | Short term |

|

||

| Pressure to decarbonize and pursue environmental friendliness in the supply chain | Decline in competitiveness due to failure to meet user needs for environmental friendliness | Decrease in sales due to failure to meet user expectations for environmental friendliness | Risk | Medium | Short term |

|

|

| Increased costs associated with switching to environmentally friendly materials | Increased costs associated with switching to electric furnace materials, recycled plastic, and bio-plastic, which emit less CO2 | Risk | Medium | Medium term |

|

||

| Increased energy procurement costs due to switching to renewable energy | Increased costs associated with in-house power generation, power purchase agreements (PPA), switching to renewable energy, and purchase of environmental value certificates | Risk | Small | Medium term |

|

||

| Expansion of the renewable energy market | Increased demand for solar power-related products and systems from producers and users of renewable energy | Increased possibility for revenue growth by expanding product and system offerings | Opportunity | Medium | Short term |

|

|

| Increased demand for zero energy houses (ZEH) | Increased possibility for revenue growth by strengthening offerings of flat-rate solar power services for homes and home energy management systems (HEMS) | Opportunity | Medium | Short term |

|

||

| Expansion of environmental protection businesses | Expansion of circular economy business models | Increased support from customers by establishing a waste-free circular economy business model, amid growing efforts for decarbonization in society | Opportunity | Small | Medium term |

|

|

| 4℃ | Intensifying weather-driven disasters | Disruptions in the supply chain | Intensifying weather-driven disasters affect Sharp suppliers and bases and the supply chain, leading to a loss in sales opportunities for Sharp | Risk | Medium | Long term |

|

- * Short term: three years or less; medium term: by around 2030; long term: by around 2050.

Greenhouse Gas Emissions Based on the GHG Protocol Initiative

Sharp calculates greenhouse gas emissions based on the GHG Protocol*1 and then works to limit those emissions resulting from customer use of Sharp products and from Sharp’s business activities, including those in the supply chain.

- *1 The GHG Protocol is an international standard for calculating greenhouse gas (GHG) emissions. It was jointly established by the World Business Council for Sustainable Development (WBCSD), a coalition of the world’s leading companies, and the World Resources Institute (WRI), a United States-based think tank.

Greenhouse Gas Emissions by Scope 1/2/3 Categories Based on the GHG Protocol Initiative (Fiscal 2022)

| Category | Emissions (Thousand Tons CO2) |

Notes | |

|---|---|---|---|

| Scope 1 (direct GHG emissions from business activities) | 331 | Emissions from combustion of fuel, etc. | |

| Scope 2 (indirect GHG emissions from energy usage in business activities) | 794 | Emissions from the use of electricity | |

| Total of Scope 1 and Scope 2 | 1,125 | ||

| Scope 3 (indirect GHG emissions from outside the scope of business activities) | 1. Purchased goods and services | 3,232 | Emissions from the manufacture of materials procured for the main products*2 that the Sharp Group sold in the reporting year |

| 2. Capital goods | 121 | Emissions from the construction, manufacture, and transportation of Sharp Group capital goods (such as equipment, machinery, buildings, facilities, and vehicles) | |

| 3. Fuel- and energy-related activities (not included in Scope 1 or 2) | 207 | Emissions from the procurement of fuels (natural resource extraction, manufacture, and transportation) consumed in the generation of electricity and heat the Sharp Group procures from other companies | |

| 4. Upstream transportation and distribution | 203 | Emissions from the transportation of Sharp Group parts and materials and products manufactured | |

| 5. Waste generated in operations | 2 | Emissions from waste disposal and treatment by the Sharp Group | |

| 6. Business travel | 2 | Emissions from business travel by all employees of Sharp Corporation | |

| 7. Employee commuting | 5 | Emissions from commuting by all employees of Sharp Corporation | |

| 8. Upstream leased assets | - | Included in Scope 1 and 2 CO2 emissions | |

| 9. Downstream transportation and distribution | 29 | Emissions from the transportation (from retailers to end consumers) of the main products*2 that the Sharp Group sold in the reporting year | |

| 10. Processing of sold products | 260 | Emissions from processing at destination of Sharp Group products | |

| 11. Use of sold products | 25,800 | Emissions*3 from the use of the main products*2 that the Sharp Group sold in the reporting year | |

| 12. End-of-life treatment of sold products | 3 | Emissions from recycling 4 types of appliances*4 that Sharp Corporation sold in Japan | |

| 13. Downstream leased assets | - | Not applicable | |

| 14. Franchises | - | Not applicable | |

| 15. Investments | - | Not applicable | |

| Scope 3 total | 29,864 | ||

| Scope 1 + 2 + 3 total | 30,989 | ||

- *2 Flat-panel TVs, air conditioners, refrigerators/freezers, washing machines/dryers, air purifiers, Plasmacluster Ion generators, microwave ovens, copiers/MFPs, solar cells.

- *3 Annual power consumption of each product × number of units sold × product life × CO2 emission coefficient.

- *4 TVs (CRT TVs, flat-panel TVs), air conditioners, refrigerators/freezers, washing machines/dryers.

Reducing Business Activity-Linked Greenhouse Gas Emissions

| Fiscal 2022 Objectives | Fiscal 2022 Achievements | Self-Evaluation | Priority Objectives for Fiscal 2025 |

|---|---|---|---|

|

|

★★ |

|

- Self-evaluation: ★★★ Achieved more than targeted / ★★ Achieved as targeted / ★ Achieved to some extent

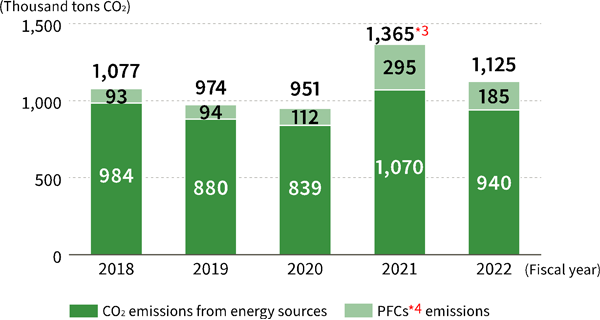

Under SHARP Eco Vision 2050—our long-term environmental vision—Sharp is aiming to achieve net-zero CO2 emissions in its business activities. To achieve our long-term environmental vision, we have set medium-term environmental goals—a 40% reduction in CO2 emissions by 2030 and a 60% reduction by 2035. We are also working to reduce GHG emissions associated with business activities. The Sharp Group’s GHG emissions from business activities in fiscal 2022 was down 17.6% to 1,125,000 tons CO2 compared to the previous fiscal year.

Each Sharp production base is strengthening efforts involving all equipment and systems—ranging from production lines to utility systems for supplying electricity, gas, and water—to boost energy efficiency and reduce GHG emissions. In particular, the LCD and electronic component plants consume large amounts of energy. The plants’ production, engineering, and environmental departments work together to reduce consumption of base-load energy. Efforts include installing inverters*1 and optimizing the air conditioning in clean rooms*2.

To achieve its environmental goals, Sharp will continue to install solar power systems in its plants and other sites, introduce factory energy management systems, streamline production lines, and install energy-saving equipment in utility systems.

- *1 A device to control the number of motor rotations.

- *2 A room where the temperature, humidity, and cleanliness are kept at controlled levels.

Sharp Group’s GHG Emissions

- *3 Includes emissions in fiscal 2021 from Sakai Display Products Corporation, which became a wholly owned subsidiary of Sharp Corporation in June 2022.

- *4 HFCs, PFCs, sulfur hexafluoride (SF6), nitrogen trifluoride (NF3).

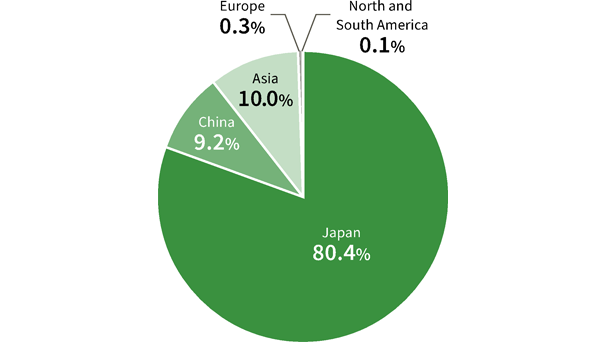

GHG Emissions by Region (Fiscal 2022)

Reducing Greenhouse Gases in the Production Process

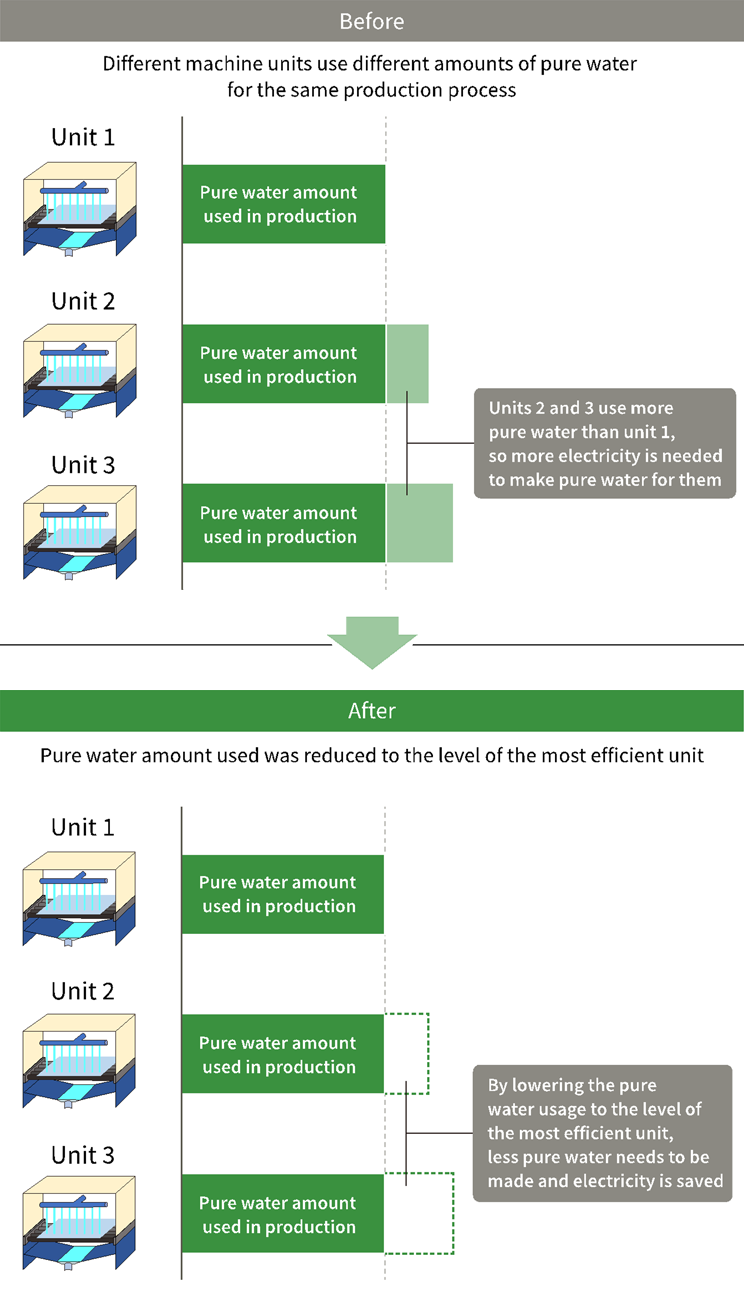

The Kameyama Plant (Kameyama, Mie Prefecture) recycles all pure water used in the production process by recovering it after use, removing impurities to once again make it pure water, and then reusing it. Previously, different units of the same machine used different amounts of pure water even though performing the same production process. But after adjusting the operating parameters of the various machine units and repeatedly confirming quality, the amount of pure water used was reduced to a unified low level. This allowed the plant to reduce the electricity needed to make pure water, resulting in an annual greenhouse gas reduction of 187 t-CO2.

Product Life Cycle Assessment

Identifying and Reducing Environmental Impacts throughout the Life of Products

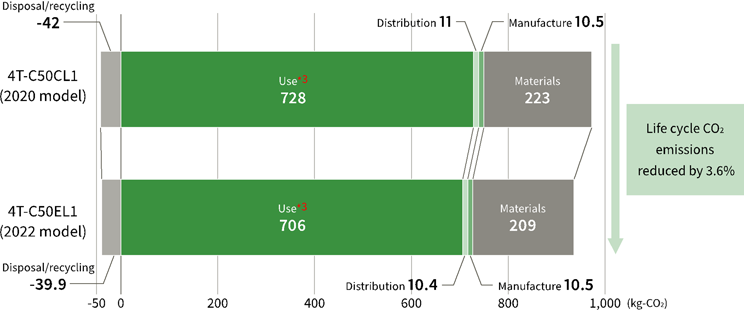

Sharp performs a life cycle*1 assessment (LCA) on its products to identify their impact on the environment throughout their service life and uses the results in product planning and development.

Consumer electronics generally have a large impact on the environment during use. Thus, by focusing on improving their energy savings, overall environmental impact can be effectively reduced. A decrease in the environmental impact of 4K*2 LCD TVs was achieved by improving energy efficiency and reducing the products’ weight.

LCA Data for 4K LCD TVs

- *1 The life of a product from materials and parts procurement to manufacture, distribution, use, disposal, and recycling.

- *2 Ultra-high-definition video standard with a resolution of 3,840 × 2,160 pixels (8.29 million pixels). This is four times the resolution of current 2K full high-definition broadcasts (1,920 × 1,080 pixels; 2.07 million pixels).

- *3 CO2 emissions during use are calculated using a CO2 emission coefficient (adjusted) announced by Japan’s Electric Power Council for a Low Carbon Society (ELCS).

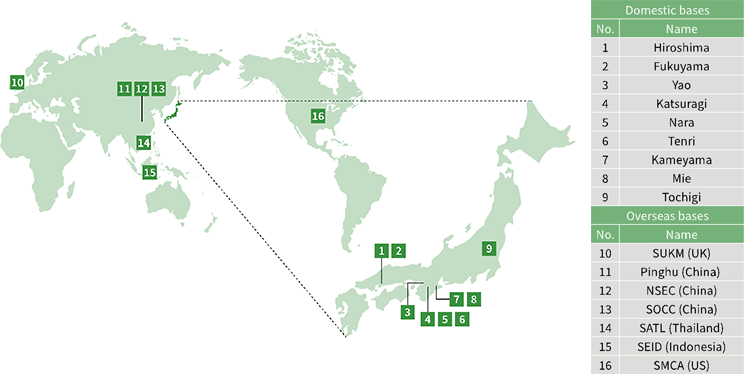

Utilizing Renewable Energy

Sharp has introduced the use of PV systems, green power, and other power sources to its domestic and overseas production bases and is advancing the use of renewables to do its part to create a decarbonized society. In fiscal 2022, the launch of new PV systems at plants in Thailand and Indonesia greatly increased the amount of Sharp’s electricity generation to 5.06 million kWh. Sharp also purchased 5.18 million kWh of green power.

This is equivalent to the annual energy consumption amount*4 of roughly 3,000 average households in Japan. Sharp will continue to expand the use of renewable energy sources.

- *4 Calculated from data from the Federation of Electric Power Companies of Japan.

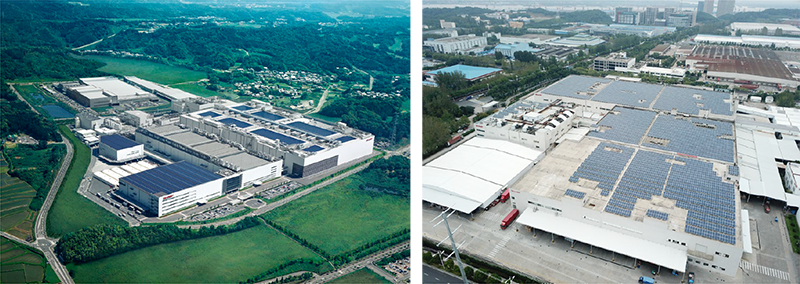

Solar Power Systems at Sharp Bases Worldwide

Solar power systems installed on the roofs of Sharp production bases (left: Kameyama in Japan; right: NSEC in China)

BLACKSOLAR ZERO Residential Solar Cell Module Wins New Energy Foundation Chairman’s Prize in 2022 New Energy Awards

Sharp’s BLACKSOLAR ZERO residential solar cell module received the New Energy Foundation Chairman’s Prize in the Products and Services category at the 2022 New Energy Awards. The awards are organized by the New Energy Foundation and supported by the Ministry of Economy, Trade, and Industry (METI).

This awards program seeks to accelerate society’s adoption of solar power and other renewable energy by honoring outstanding developments in renewable-energy-related products and services, and applications of distributed energy.

BLACKSOLAR ZERO can be efficiently installed on various shapes of roofs thanks to its Roofit design: four types of modules, each a different size or shape, are combined to match the exact size and shape of a roof. This squeezes maximum power generation from available roof space and makes it possible to achieve large power generation capacity even for installations on limited-space or complex-shaped roofs, such as those in urban areas.

The New Energy Awards judging panel also gave high marks to the look of BLACKSOLAR ZERO. With all four module types completely black, a unified sense of design is realized. Joints between adjacent modules are inconspicuous and the installation harmonizes beautifully with the roof.

Sharp will continue to contribute to the creation and spread of clean energy through greater dissemination of its solar power generation and storage battery systems.

New Energy Awards logo

Conceptual image of BLACKSOLAR ZERO installation

Installing Solar Power Systems at Production Bases

Sharp’s production bases are installing solar power systems to make full use of renewable energy and help achieve a decarbonized society. In December 2022, Thai production base SATL installed a PV system with an output of roughly 2.45 MW-dc. This system is expected to generate around 3,480 MWh annually, which is enough to cover about 10% of the plant’s electricity use. In January 2023, the SOCC production base in China installed a 4.73 MW-dc PV system, which is expected to generate around 4,950 MWh annually. This is enough to cover about 50% of the plant’s electricity use. Sharp will continue to actively use renewable energy sources.

Solar power systems installed on the roofs of Sharp production bases (left: SOCC in China; right: SATL in Thailand)

Reducing Logistics-Related Environmental Impact

Reducing the Environmental Impact of Logistics in Japan

Sharp observes a rule set forth in the Japanese Act on the Rational Use of Energy (Energy Conservation Act) that requires specified shippers to reduce energy intensity by 1% or greater per year. All Sharp Group companies in Japan are working to reduce the environmental impact and costs associated with logistics.

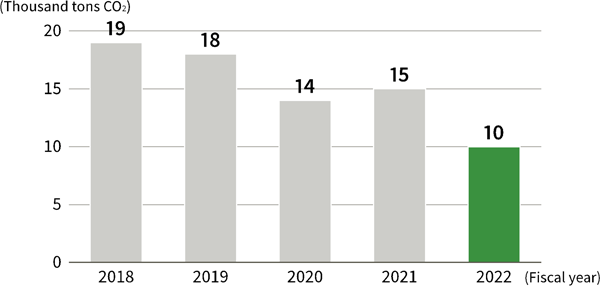

In fiscal 2022, Sharp Group greenhouse gas (GHG) emissions from shipping activities in Japan were down 34% from the previous fiscal year to 10,000 tons CO2. For Sharp Corporation, energy intensity was improved by an average of 8.6% for the most recent five years (fiscal 2018 to 2022). Sharp is steadily implementing a modal shift*1, a change from conventional trucking to more environmentally friendly modes of transport, such as shipping (non-international coastal trading vessels) and rail (Japan Railways containers). And, by unloading imported goods at harbors chosen for their proximity to their main sales locations, Sharp is reducing re-transport between distribution centers. These efforts enable Sharp to reduce the environmental impact of its distribution activities. For shipments, Sharp has been certified with an Eco Rail Mark*2 by the Ministry of Land, Infrastructure, Transport, and Tourism and the Railway Freight Association.

- *1 To shift freight transport from conventional trucking to more environmentally friendly modes of transport, such as rail and shipping.

- *2 Products or companies that use a certain amount of rail transport for freight are given Eco Rail Mark certification. The mark is used on items such as product packaging and brochures to inform the public that a company uses environmentally friendly modes of transport.

GHG Emissions from Freight Shipments (Japan)

Eco Rail Mark certification

Reducing the Environmental Impact of International Logistics

Sharp has a wide range of initiatives to reduce the amount of GHGs that are emitted as a result of international shipping. The company is reducing airfreight volume as it switches to environmentally friendly modes of transport, and it is also improving load efficiency. Further, it is reviewing shipping routes and switching to harbors that are closer to the final destinations for products. Sharp is also switching to suppliers located closer to its factories. In fiscal 2022, Sharp’s GHG emissions from international transport were 138 thousand tons CO2.