Environmental Management

Putting Sustainable Management into Practice

In accordance with internal environmental conservation guidelines established in line with Sharp’s Basic Environmental Philosophy, the Sharp Group Charter of Corporate Behavior, and the Sharp Code of Conduct, Sharp is pursuing environmental consciousness across all of its business activities.

Toward realizing a sustainable global environment, Sharp has formulated SHARP Eco Vision 2050, a long-term environmental vision with 2050 as the target year. Under this vision, Sharp is striving to solve social problems and continuously raise corporate value through the development of technologies and the provision of products and services.

Promoting Sustainable Management

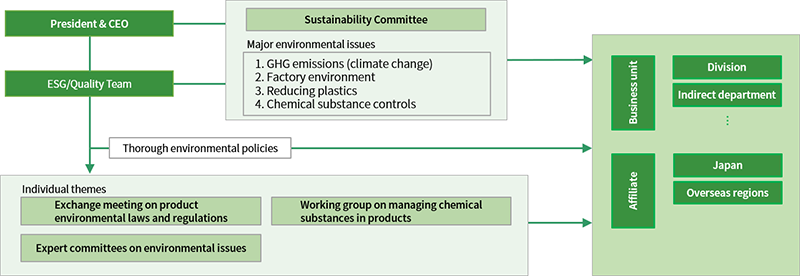

Sharp has set up the ESG/Quality Team to formulate and carry out the company’s environmental vision, policies, and targets, and to strengthen environmental governance.

The ESG/Quality Team formulates important environmental policies, strategies, and measures at the corporate level regarding sustainable management based on Sharp’s management policies and environmental vision. The Sustainability Committee includes the President & CEO, senior executives, and the heads of Sharp business units and subsidiaries. Through this committee, the ESG/Quality Team confirms progress toward environmental goals and supports environmental activities.

In the area of product environmental laws and regulations and chemical substance controls, we periodically hold information exchange meetings to ensure compliance with applicable requirements. Working groups and expert committees are also established as required to address environmental issues that call for cross-functional efforts.

System for Promoting Sustainable Management in the Environmental Area

Environmental Education

In accordance with the basic strategy of its management policy—foster and strengthen human resources—Sharp strives to step up the cultivation of human resources as the foundation of its sustainable management. To this end, the company has been providing training programs, including basic training open to all employees.

Since fiscal 2019, Sharp has held environmental awareness training to help all employees acquire a wide range of environmental knowledge, and an introductory training course on environmental laws and regulations, which is mandatory for third-year employees.

In fiscal 2022, Sharp held training on product environmental laws and regulations. Individual plants also held their own training sessions. For example, the Katsuragi Plant (Katsuragi, Nara Prefecture) held a session on environmental management systems for environmental committee members and training for employees who handle chemical solutions and gases. At SSEC, Sharp’s production base in China, employees underwent online training led by outside experts on energy conservation and energy-saving best practices.

With the aim of fostering human resources who will contribute to the company in stepping up compliance and achieving its environmental vision, Sharp will continue to improve and expand its environmental education curricula by adjusting them to different duties and roles.

Environmental Performance Data Collection and Management

To support sustainable management, Sharp has established a system for efficiently collecting and managing data on Sharp’s environmental performance, including energy consumption, waste generation, water usage, and chemical substances handled in Sharp’s business activities. This system is in operation at Sharp bases in Japan and overseas. Collecting and analyzing such data helps Sharp grasp the current state of its sustainable management, identify problems, and formulate measures.

Promoting an Environmental Management System

Since 1995, Sharp has been operating an ISO 14001-based environmental management system and has acquired ISO 14001 certification for all worldwide production bases. The purpose of this system is to strengthen environmental sustainability management and improve the environmental awareness of employees.

ISO 14001 was revised in fiscal 2015. It now requires companies to further their efforts with a more strategic perspective—for example, by integrating their environmental activities with business activities. In response to the revision, Sharp is operating a more effective environmental management system that matches the particular needs of each base.

Product and Plant Audits

Sharp regularly carries out a Green Product/Green Device Audit aimed mainly at ensuring compliance in product development. The company checks compliance with the environmental laws and regulations of each country and the reflection of environmentally friendly design in products, such as energy efficiency, resource savings, and recyclability.

Sharp also reviews and evaluates environmental activities at its production bases as part of the CSR self-assessment survey. To strengthen governance and reduce risks, our survey in fiscal 2022 was focused on interviews at sites that have just joined the Sharp Group through M&A or other partnerships.

Legal Violations, Accidents

In fiscal 2022, Sharp was not subject to any lawsuits or fines related to environmentally related legal violations. There were also no major environmentally related accidents.

Developing Environmentally Conscious Products and Devices

Developing Green Products and Devices

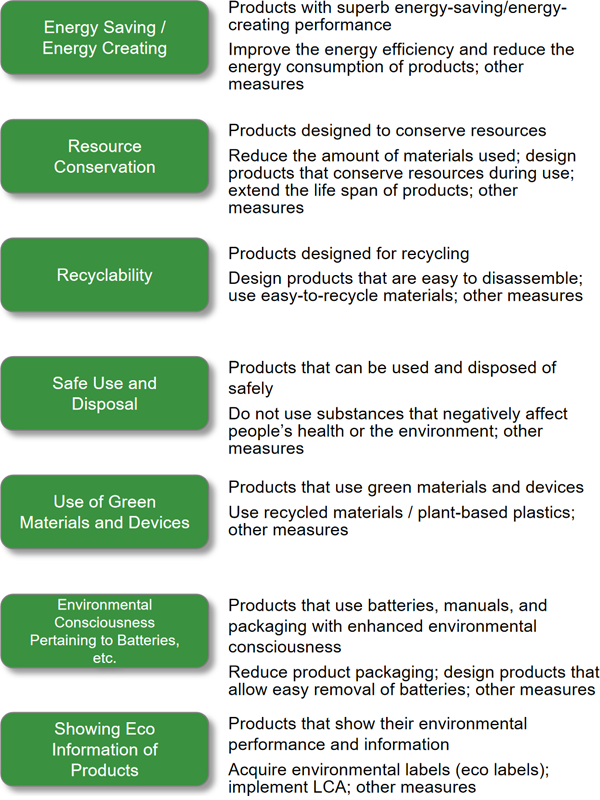

Sharp calls its environmentally conscious products “Green Products (GP).” The GP Guidelines, which define development and design criteria in line with seven concepts, have been in use at all product design departments since fiscal 1998. In developing products, Sharp sets specific objectives according to the GP Standard Sheet, which is formulated based on the GP Guidelines. In the trial manufacture and mass production stages, it determines how well the actual product has met these objectives. The content of the GP Standard Sheet—the benchmark for development objectives—is revised each year in order to constantly improve the environmental performance of Sharp products. Sharp sales and manufacturing bases in Europe, ASEAN countries, and the Middle East meet periodically to keep abreast of changing product environmental laws and regulations around the world. The information gathered at these meetings is shared with Sharp business units in Japan and the legal requirements relating to product design are reflected in the GP Guidelines.

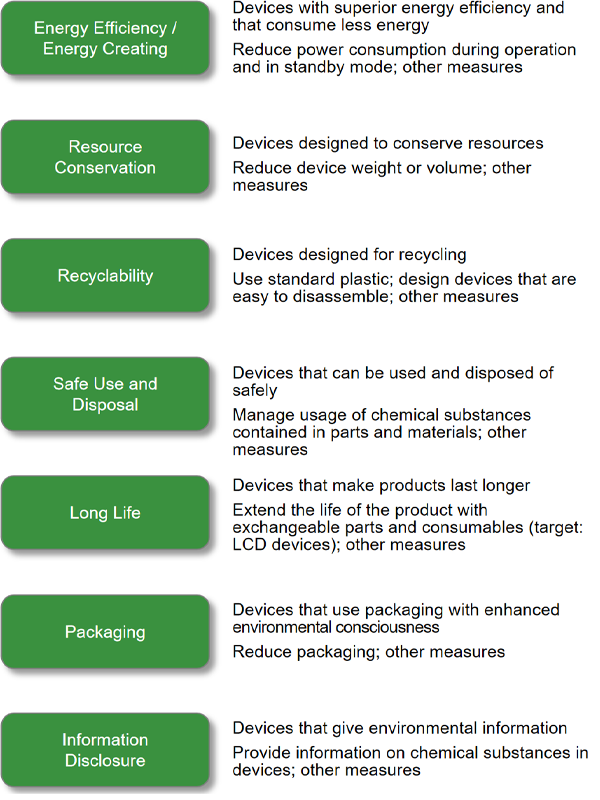

Sharp calls its environmentally conscious devices “Green Devices (GD).” To define guidelines for development and design based on seven concepts, Sharp established the GD Guidelines, which it began applying at all device design departments in fiscal 2004. Sharp sets objectives according to the GD Standard Sheet and assesses how objectives have been met in a similar way to GP standards. In fiscal 2013, Sharp revamped the GD assessment system by adding new criteria concerning forward looking initiatives that take customer demands into consideration. The degree to which these criteria are satisfied is represented in points called GD Challenge Points. The assessment criteria are revised every year so that Sharp can continuously raise the environmental performance of its products such as LCD modules and sensors.

Green Product Concepts

Green Device Concepts

Developing Super Green Products

Since fiscal 2004, Sharp has been certifying products that offer a particularly high level of environmental performance as “Super Green Products (SGP).” In fiscal 2022, sales of those products reached 131.2 billion yen, with SGP sales accounting for 28% of all GP sales in Japan.

In fiscal 2016, Sharp revised the criteria for this certification. Products are certified if (1) they offer class-leading energy-saving or energy-creating performance, or (2) they offer significantly high environmental performance through the use of unique Sharp technology. This way, Sharp is aggressively pursuing the development of products that consume as little power as possible or that use resources to the least possible extent, as well as developing high-efficiency solar cells.

Examples of Super Green Products

Plasmacluster washing machine/dryer

ES-X11A

Smartphone

AQUOS sense7

Digital full-color MFP

BP-70C45

Solar module

NU-259AM

Developer Interviews

Sharp has the “Always Thinking Green” website, which features interviews with product planning staff, engineers, designers, and other staff involved in product development. The site conveys their commitment to environmentally conscious manufacturing and the difficulties they have faced. Through this site, Sharp aims to boost the added value of products by communicating the products’ appeal from an environmental perspective.

In fiscal 2022, the site featured AQUOS wish/wish2 smartphones and a front-loading washer/dryer.

The smartphone development team

The front-loading washer/dryer development team

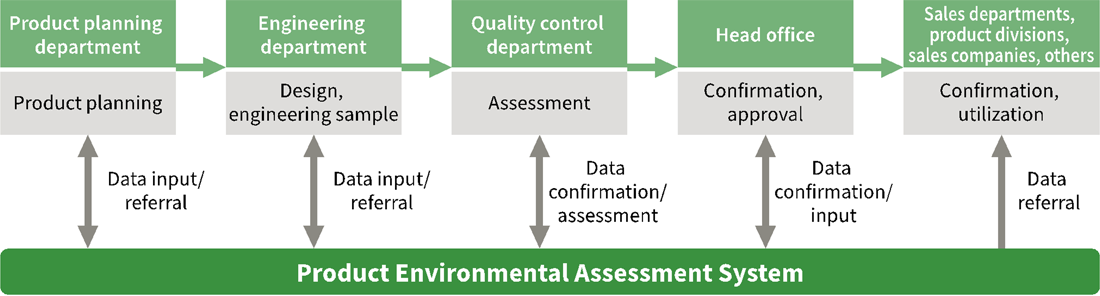

Product Environmental Assessment System

Sharp operates a product environmental assessment system to ensure compliance with environmental laws and regulations as well as to promote environmentally conscious product design. This system allows Sharp to keep a database of the development know-how and design data that all Sharp design and development bases possess on environmentally conscious products and devices. The database is used to raise design standards and to promote in-house standardization of life cycle assessments (LCA). This way, the system is contributing to the creation of environmentally conscious Sharp products and devices. Since fiscal 2016, Sharp has been strengthening the function for checking products’ compliance with environmental laws and regulations.

System Flow