Resource Recycling

Minimizing and Recycling Business Activity-Linked Waste

| Fiscal 2022 Objectives | Fiscal 2022 Achievements | Self-Evaluation | Priority Objectives for Fiscal 2023 |

|---|---|---|---|

|

|

★★★ |

|

- Self-evaluation: ★★★ Achieved more than targeted / ★★ Achieved as targeted / ★ Achieved to some extent

Curbing the Amount of Waste, etc. Generated by the Sharp Group

Sharp has been working to reduce waste and to recycle as much of it as possible in an effort to contribute to building a circular economy.

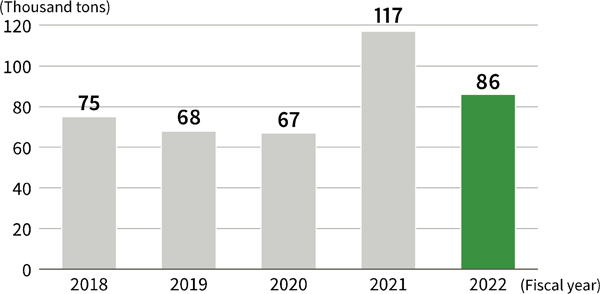

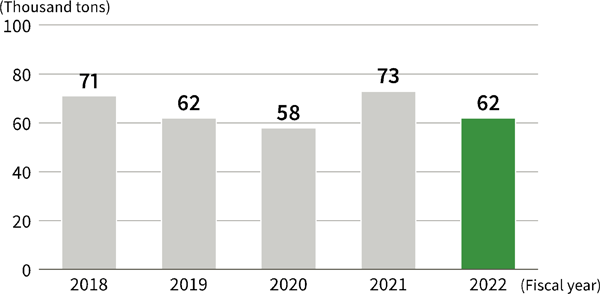

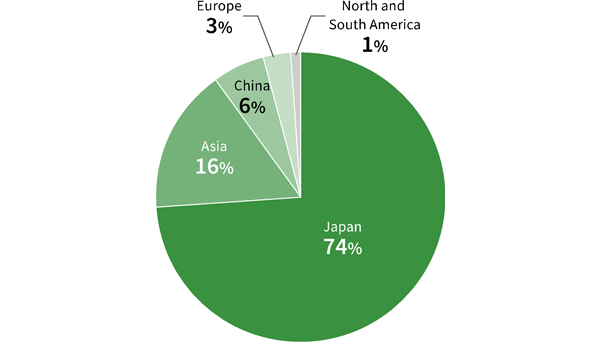

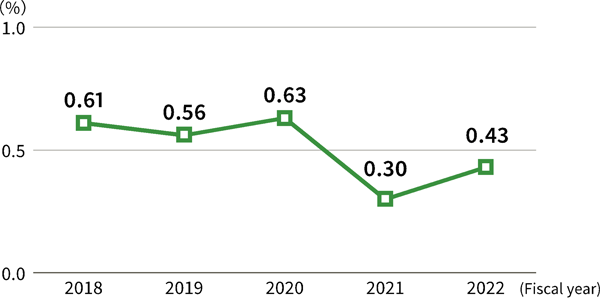

In fiscal 2022, the amount of waste, etc. generated by the Sharp Group decreased by 27% compared to the previous fiscal year to 86,000 tons, due to disposal of old equipment and expansion of production. The amount of recycling decreased by 15% from the previous fiscal year to 62,000 tons. Meanwhile, by reducing landfill disposal rates at overseas bases, the Sharp Group’s final landfill disposal rate was 0.43%, thus achieving zero discharge to landfill* on a global scale.

Sharp will continue to strengthen waste-reduction efforts at overseas bases while maintaining global zero discharge to landfill.

- * Sharp defines “zero discharge to landfill” as a final landfill disposal rate of less than 0.5%. Final landfill disposal rate (%) = Amount of landfill disposal ÷ amount of waste, etc. generated × 100.

Amount of Waste, etc.

Amount of Recycling

Waste, etc. by Region (Fiscal 2022)

Final Landfill Disposal Rate

Appropriate Storage and Management of PCB Wastes

In Japan, Sharp properly stores and manages waste PCB (polychlorinated biphenyls) in accordance with the Act on Special Measures Concerning Promotion of Proper Treatment of PCB Wastes. Sharp has completed processing of all high-concentration waste PCB in fiscal 2022. As for the remaining low-concentration waste PCB, Sharp is on track to finish processing them at the earliest date possible.

Reducing Consumption of Plastic

SPC, a Sharp production and sales base in the Philippines, reuses the plastic bags that are generated as waste in the LCD TV production process. The plastic bags used for wrapping LCD TV parts were previously disposed of as industrial waste, but by collecting them during production they can now be used in the packaging process of finished products that are shipped out. This has allowed SPC to reduce monthly plastic bag usage by approximately 12,000.

Unpacking parts

Preparing to collect and reuse the plastic bags during parts unpacking

Expanding the Recycling of Used Products

| Fiscal 2022 Objectives | Fiscal 2022 Achievements | Self-Evaluation | Priority Objectives for Fiscal 2023 |

|---|---|---|---|

|

|

★★★ |

|

- Self-evaluation: ★★★ Achieved more than targeted / ★★ Achieved as targeted / ★ Achieved to some extent

Sharp’s Stance on Recycling Used Products

Sharp collects and recycles used products in compliance with the recycling laws and regulations of the respective country or region. Through the effective use of limited resources, Sharp is contributing to the realization of a sustainable society.

Japan

Recycling 4 Kinds of Home Appliances in Japan (Air Conditioners, TVs, Refrigerators, and Washing Machines)

As a member of the B Group*1 for home appliance recycling, Sharp has constructed—and is operating—a highly efficient recycling system consisting of 17 recycling plants in Japan. In fiscal 2022, Sharp collected 2.314 million units (down 1% over the previous fiscal year) of the four types of appliances covered by the Home Appliance Recycling Act. The processed and recycled weight amounted to approximately 69,000 tons (down 1% over the previous fiscal year). For all four appliance types, Sharp’s rate of recycling exceeded the legally stipulated levels.

- *1 The B Group consists of Sharp Corporation, Sony Corporation, Hitachi Global Life Solutions, Inc., Fujitsu General Ltd., Mitsubishi Electric Corporation, and other companies.

Sharp Corporation’s Recycling Results for 4 Home Appliance Types (Fiscal 2022)

Note: All figures are rounded down to the nearest whole number.

| Unit | Air Conditioners |

CRT TVs |

Panel TVs |

Refrigerators/ Freezers | Washing Machines/ Dryers | Total | |

|---|---|---|---|---|---|---|---|

| Units collected from designated collection sites | Thousand units | 331 | 87 | 957 | 470 | 466 | 2,314 |

| Processed and recycled units | Thousand units | 336 | 88 | 964 | 476 | 478 | 2,344 |

| Processed and recycled weight | Tons | 13,707 | 1,943 | 15,296 | 28,330 | 19,091 | 78,367 |

| Recycled weight | Tons | 13,087 | 1,444 | 13,334 | 22,832 | 17,998 | 68,695 |

| Recycling rate | % | 95 | 74 | 87 | 80 | 94 | - |

| Legally required recycling rate | % | 80 | 55 | 74 | 70 | 82 | - |

Toward Making Better Use of Resources

Sharp and Kansai Recycling Systems Co., Ltd.*2 have joined forces to make effective use of resources and to improve recycling efficiency.

The motor of a washing machine uses copper windings. Separating and recovering materials like copper can boost the value of resources. Conventional equipment used a rotary blade to cut the copper winding, but the dust resulting from the cutting could potentially have an adverse effect on the operator’s health or the functioning of the machine. In addition, to prevent aluminum—an increasingly common winding material—from getting mixed with copper, aluminum windings were dismantled by hand in a separate process.

In fiscal 2022, we introduced a multi-axis robotic arm to automate the cutting/recovery process. The robot cuts and recovers the copper windings and aluminum windings from the motors, using a dedicated cutting device for each type of material. Switching to a dust-free cutting method has greatly improved the work environment. Using a single piece of machinery to separate copper and aluminum has reduced the processing time per motor by about 30%.

- *2 A consumer electronics recycling company established in Japan with joint investment from Sharp, Mitsubishi Materials Corporation, and four other companies.

The multi-axis robotic arm automates the cutting/recovery process

Recovered copper windings

Design-for-Recycling Training

Sharp is committed to considering the whole life cycle of products it manufactures. Together with Kansai Recycling Systems—where four kinds of Sharp products are recycled—Sharp has been holding design-for-recycling training for product planners and designers. In April 2023, 13 people, including those in charge of white goods, took part in the training.

The training emphasized the importance of designing products with an eye to their eventual recycling, with a focus on plastic material recycling. It also included a tour of the recycling plant. Participants practiced dismantling a fully automatic washing machine that had been used for over a decade. They saw how the ease of dismantling depends on the fastening method used—for example, whether the product is held together with screws. They also learned the importance of separating components into discrete material types.

Participants gained a better understanding of the recycling process, and expressed a desire to focus on achieving both quality and recyclability in their future designs. We will continue to foster awareness within the company so that we can pursue manufacturing that considers everything from material selection to end-of-life recycling.

Classroom lecture

Dismantling a washing machine

Reusing and Recycling Copiers and MFPs in Japan

Sharp is reusing and recycling copiers and MFPs collected both through Sharp distribution channels and through common industry channels. The company is also collecting used toner cartridges and remanufacturing them to the same quality standard of new products, thus assuring that customers will always get the same high quality. Sharp designs its toner cartridges for easy reuse and recycling. This ensures durability and reduces the amount of time needed to reprocess used cartridges.

Recycling Used Products Overseas

North America

In 2007, Sharp’s American manufacturing and sales base SEC established MRM (Electronic Manufacturers Recycling Management Company, LLC)*1 to manage recycling of AV products. Growing nationwide efforts have seen a total of 2,900 collection points established for used products. MRM operates in accordance with the laws and regulations of each state and recycled a total of 60,000 tons of used products in fiscal 2022.

- *1 MRM is a joint venture with Panasonic Corporation of North America and Toshiba America Consumer Electronics, LLC.

Europe

The EU WEEE Directive*2 (2012/19/EU) stipulates that the manufacturer is responsible for collecting and recycling products shipped within the EU. Each Sharp European sales base collaborates with established recycling entities in the EU sales region to meet this requirement. Efforts are also made to reduce the volume of landfill waste by taking into account regulations governing packaging materials and batteries.

SBSUK, Sharp’s sales base in the UK, won a Greener Path Landfill Diversion Award for achieving zero final landfill disposal in fiscal 2022.

- *2 Waste Electrical and Electronic Equipment Directive

Green Path Landfill Diversion Award logo

Vietnam

In Vietnam, the introduction of a recycling law in 2017 has obliged manufacturers and importers to establish a collection scheme for products sold within the country. SVN, Sharp’s Vietnamese sales base, collects used products at collection points established in Vietnam and ensures they are processed appropriately by licensed recyclers for proper disposal.

India

In India, the E-Waste (Management) Rules—which came into effect in 2016 and were amended in 2022—require manufacturers and others to properly dispose of used electronic/electrical equipment. SBI, Sharp’s Indian sales base, has partnered with a local recycler, 3R Recycler, to carry out the recycling of used products.

The Plastic Waste Management Rules, which also came into effect in 2016, require manufacturers, importers, sellers, and regional governments to properly process plastic waste. SBI works with a local NGO, the Indian Pollution Control Association, to collect and recycle plastic waste.

Environmental Technologies That Contribute to a Sustainable, Recycling-Based Society

| Fiscal 2022 Objectives | Fiscal 2022 Achievements | Self-Evaluation | Priority Objectives for Fiscal 2023 |

|---|---|---|---|

|

|

★★ |

|

- Self-evaluation: ★★★ Achieved more than targeted / ★★ Achieved as targeted / ★ Achieved to some extent

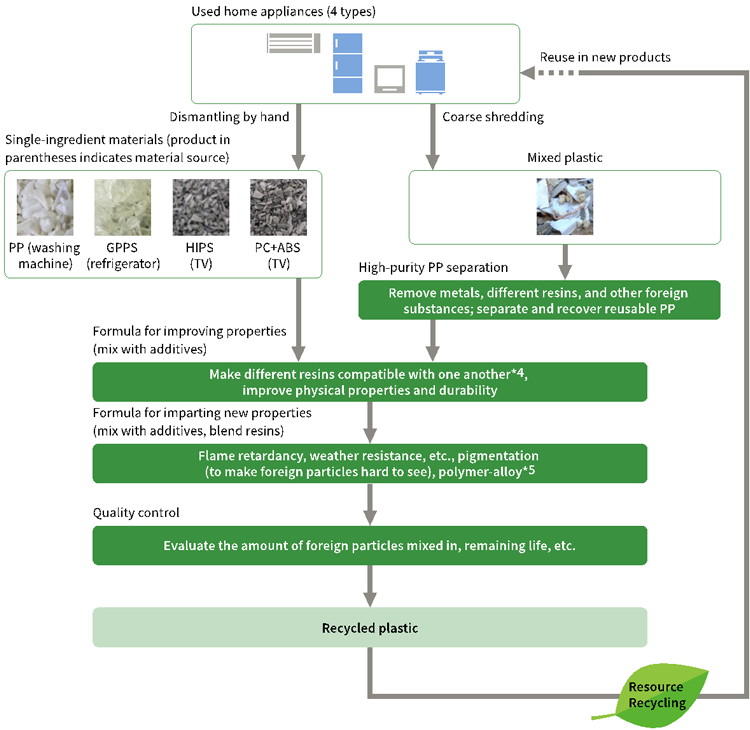

Expanding Closed-Loop Plastic Material Recycling Technology

In recycling materials, such as when end-of-life plastic is reused to make new products, the open-loop material recycling scheme is commonly adopted. It involves reusing recycled materials to make things like daily necessities and sundries. The majority of these are used only once and disposed of as municipal waste.

As opposed to this type of recycling, Sharp and Kansai Recycling Systems Co., Ltd.*1 jointly developed closed-loop plastic material recycling technology with a view to making better use of finite resources and reducing waste. This technology enables the repeated recovery of plastic from used consumer electronics products as well as the reuse of that plastic in parts of new consumer electronics products. The technology has been in practical use since fiscal 2001, when the Act on Recycling of Specified Kinds of Home Appliances (Home Appliance Recycling Act) was enacted in Japan.

Sharp has been striving to make more plastic recyclable through the development of new technologies. These include a technology for recovering high-purity polypropylene (PP) from mixed plastic parts and parts that contain metal; a technology for improving the properties of recovered PP/HIPS*2 and PC+ABS*3 materials so that their quality is on a par with that of virgin materials; a technology that gives materials added value by imparting properties such as flame retardancy, weather resistance, and an antibacterial property, with the aim of expanding applications for recycled plastic; and a quality-control technology for ensuring optimal quality. Thanks to the development and introduction of these technologies that integrate everything from recovery to quality control, Sharp has been able to establish closed-loop material recycling to produce high-grade recycled plastic.

- *1 A consumer electronics recycling company established in Japan with joint investment from Sharp, Mitsubishi Materials Corporation, and four other companies.

- *2 High-impact polystyrene (general-purpose polystyrene [GPPS] given impact resistance by adding rubber).

- *3 A polymer alloy of polycarbonate and acrylonitrile, butadiene, and styrene (a resin given new properties as a result of mixing in several types of polymers).

Recycling Plastic Recovered from the 4 Types of Home Appliances

- *4 Blending multiple types of resins uniformly and finely dispersed into one another at the molecular level.

- *5 A resin given new properties as a result of mixing in several types of resins.

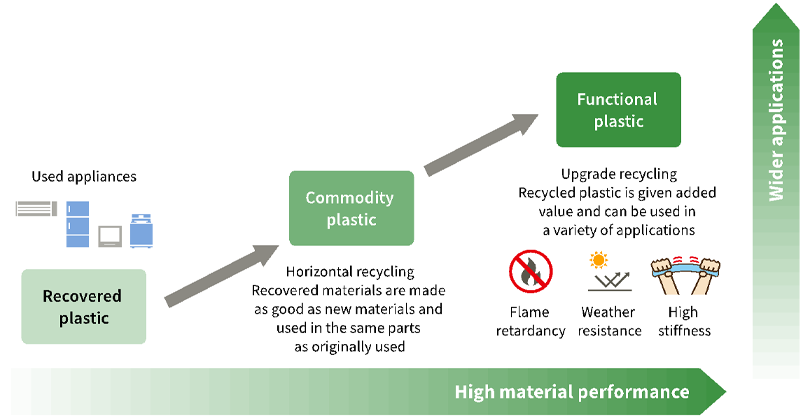

Developing Recycled-Plastic Material with Added Value

In response to the increasing seriousness of pollution from used plastic, countries are enacting and enhancing various laws and regulations related to plastic recycling. There is a push to move away from the traditional linear economy, characterized by mass production, mass consumption, and mass disposal, and towards a circular economy, characterized by limited input and consumption of new resources and minimal waste production. In Japan, as well, society’s attitude towards plastic usage has changed significantly, as evidenced by the enforcement of the Act on Promotion of Resource Circulation for Plastics*. The Act focuses on resource recycling across the entire life cycle of plastic products, making it increasingly important that plastic materials are properly disposed of and recycled.

Against this background, Sharp is pursuing greater recycling of used plastics, not only through horizontal recycling, in which used plastics are made as good as new material and incorporated into the same parts as they were originally used, but also through upgrade recycling, in which the recycled plastic is given added value with flame retardancy, weather resistance, or high stiffness.

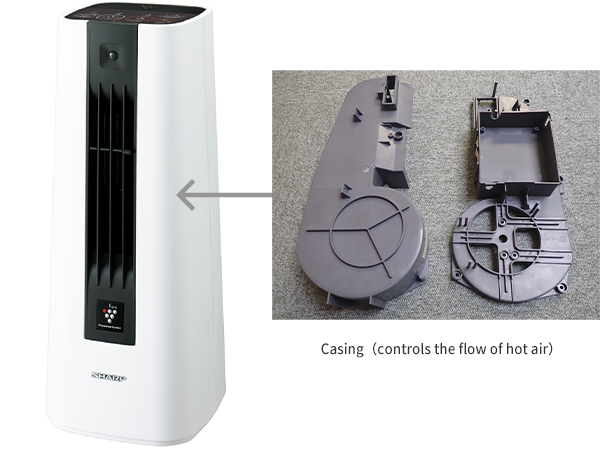

In fiscal 2022, Sharp developed mass-production technology for recycled flame-retardant polypropylene and used the material in the internal parts of ceramic fan heaters. Polypropylene recovered from used home appliances is given the physical properties, flame resistance, and long-term durability demanded in home appliances using Sharp’s own formulation technology.

Recycled flame-retardant polypropylene is difficult to make using conventional methods. This is because it requires mixing recovered polypropylene with a thermally decomposable flame retardant and multiple modifiers under high temperature. Sharp’s new formulation and optimized process have enabled the mass production of high-performance, high-quality recycled flame-retardant material. This recycled material can be used in place of metal in parts that require a high level of safety, such as those used around power switches and heat sources. The practical application of this recycled plastic material holds promise for lighter and cheaper products, while also curbing the generation of waste plastic.

Going forward, Sharp will develop recycled materials that use no environmentally harmful substances such as halogen compounds, thereby contributing to a circular economy.

- *This law is focused on comprehensive plastic recycling across the entire life cycle of plastic-containing products, encompassing everything from manufacturer product design and production to waste disposal (effective as of April 1, 2022).

Used Plastic Recycling Method

Using Recycled Flame-Retardant Polypropylene

Recycled flame-retardant polypropylene

Ceramic fan heater

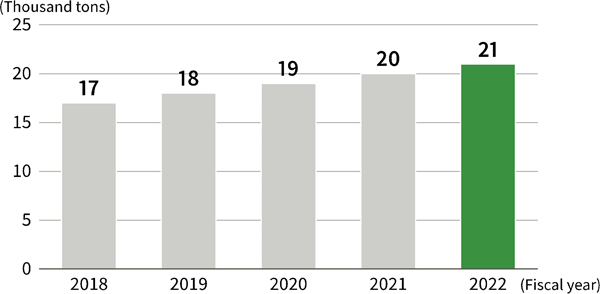

The use of recycled plastic developed through Sharp’s own closed-loop material recycling technology was extended to refrigerators, air conditioners, washing machines, and small appliances released in fiscal 2022. In fiscal 2022, the cumulative total amount used since 2001 reached 21,000 tons.

Amount of Recycled Plastic Used

Examples of Recycled Plastic Use

Refrigerator

Washing machine

Air conditioner

Car Plasmacluster Ion generator

Handheld device (Handy Terminal) charger

Ceramic fan heater

| Product | Recycled Plastic | Part | Source |

|---|---|---|---|

| Refrigerator | PP | Divider | Refrigerator vegetable case |

| Duct cover | Refrigerator vegetable case | ||

| Handgrips | Washing machine top plate, outer cabinet, other | ||

| Evaporator cover | Washing machine spin tub, balancer, other | ||

| Flame-retardant PS | Substrate holder | Flat-panel TV back cabinet + refrigerator tray | |

| Washing machine | PP | Washing tub | Washing machine tub |

| Air conditioner | PP | Condensation cover, motor holder | Washing machine spin tub, balancer, other |

| Vertical louver, interlocking plate | Refrigerator vegetable case | ||

| Flame-retardant PS | Substrate holder, substrate spacer | Flat-panel TV back cabinet + refrigerator tray | |

| Car Plasmacluster Ion generator | Flame-retardant PC + ABS | Internal parts | Flat-panel TV back cabinet |

| Handheld device (Handy Terminal) charger | Flame-retardant PC + ABS | Charger | Flat-panel TV back cabinet |

| Ceramic fan heater | Flame-retardant PS | Casing | Air conditioner, refrigerator, and washing machine parts |

Environmentally Conscious Products

AQUOS wish3 Smartphone Uses Significantly More Recycled Plastic

Sharp released its AQUOS wish3 basic model smartphone in July 2023. The third edition of a smartphone series whose simplicity matches a user’s straightforward lifestyle, the wish3 is environmentally friendly and has a wealth of functions that are easy to use for the entire family.

This model continues with the lauded features of the AQUOS wish series, such as a smooth surface texture and a range of gentle, sophisticated color choices. In addition to its compact and easy-to-hold size and simple design, the wish3 is highly resistant to water, dust, and impact*1.

The use of recycled plastic in the wish3’s casing has been upped to approximately 60%*2. It now also adopts*3 recycled plastic around the camera and in some interior parts. And adding to the phone’s environmental friendliness is its use of a small and simple package using less paper than before.

The wish3 also includes Junior Mode, a new feature for children using a smartphone for the first time. The mode’s wealth of safety features includes Google Family Link for preventing the child’s overuse of the phone, and an emergency SOS signal activated by multiple pushes of the power button. Add the wish3’s Easy Mode giving large, bold onscreen text that even older users can read, and you have a smartphone offering usability and convenience for the whole family.

The wish3’s camera incorporates ProPix4 lite, Sharp’s new image engine using the high-quality-image technology of Sharp’s flagship model AQUOS R7. Users can easily take gorgeous photos thanks to features like AI Auto, which chooses the optimal image mode by automatically detecting the subject and surroundings, and Auto HDR, which takes great photos even against a bright backlight.

- *1 Tested for compliance with MIL-STD-810H, a standard of the United States Department of Defense for ensuring a product can withstand the conditions under which it will be used. There is no guarantee the product will not break or malfunction under all types of impact.

- *2 The AQUOS wish2, released in fiscal 2022, used approximately 35% recycled plastic.

- *3 Parts other than the casing use approximately 35% recycled plastic.

(Left) AQUOS wish3 in white, black, and green (Right) Conceptual image of recycling

Effectively Using Water Resources

| Fiscal 2023 Objectives |

|---|

|

Sharp’s Stance on Water Resources

Water resource problems are arising on a worldwide scale with the increase in the world’s population, the economic growth of developing countries, climate change, and other factors. Sharp is striving to make effective use of water resources in line with the environmental conservation guidelines stipulated in Sharp’s Basic Environmental Philosophy, the Sharp Group Charter of Corporate Behavior, and the Sharp Code of Conduct. In particular, Sharp recognizes that securing the water resources necessary for the production of LCDs and other electronic devices is a serious issue that could affect business continuity. That is why Sharp is pursuing the reduced use of new water and an increased use of recycled water.

Reducing the Amount of New Water Used and Using More Recycled Water

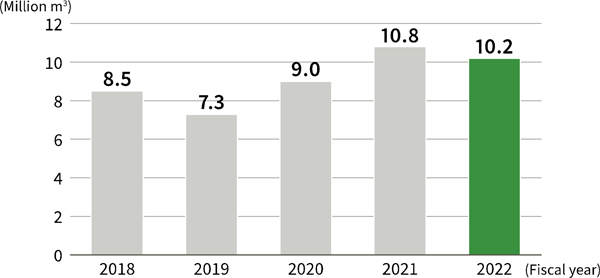

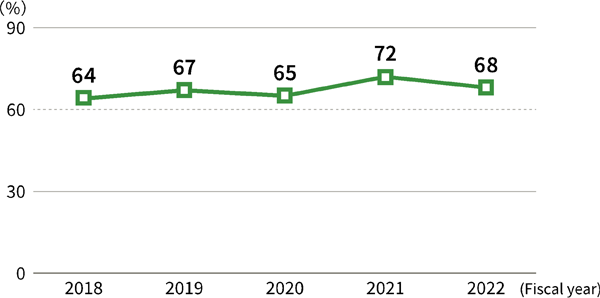

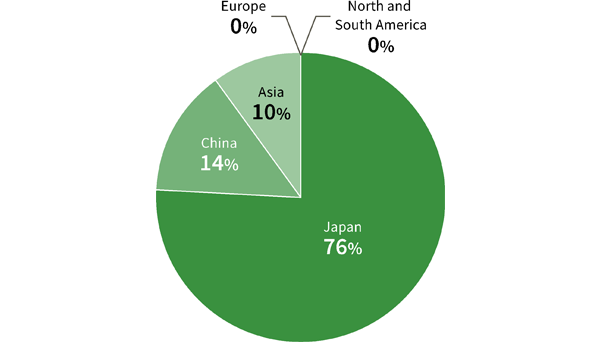

The volume of new water used by the Sharp Group in fiscal 2022 decreased by 6% compared to the previous fiscal year to 10.2 million m3. To minimize the effects on business continuity of the risk of water shortages, Sharp assesses water risk at its plants using the Aqueduct assessment tool developed by the World Resources Institute (WRI). SATL, Sharp’s production base in Thailand, is located in an area of highest risk. It is therefore reducing its use of new water by recycling water discharged from the production process and other sources. The Kameyama Plant (Kameyama, Mie Prefecture, Japan) and the Mie Plant (Taki District, Mie Prefecture, Japan) require a large amount of water in the production process for LCDs and other products. All of the water discharged from the production process is collected and reused via a closed-loop recycling system adopted at both plants. Through measures such as this, the Sharp Group is maintaining a recycling rate* of at least 60%. Looking ahead, Sharp will pursue further water-use efficiency worldwide and boost production efficiency in accordance with business expansion.

In fiscal 2022, there were no litigation issues, fines, or penalties due to violations of water-related laws and regulations. There were also no serious water-related accidents.

- * Recycling rate = Amount recycled ÷ (amount of new water + amount recycled).

Volume of New Water Used

Water Recycling Rate

New Water Used by Region (Fiscal 2022)

Water Used and Drainage by Region (Fiscal 2022)

(m3)

| Region | Water withdrawal*1 | Effluent | Amount consumed*3 | Amount recycled | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Third-party water*2 | Groundwater | Total | Surface water | Sewerage | Seawater | Groundwater | Total | |||

| Japan | 7,018,688 | 757,353 | 7,776,041 | 3,800,411 | 343,123 | 1,990,662 | 0 | 6,134,196 | 1,641,845 | 21,063,228 |

| Asia | 974,903 | 14,854 | 989,757 | 36,561 | 532,347 | 0 | 0 | 568,908 | 420,849 | 115,310 |

| China | 1,362,880 | 29,883 | 1,392,763 | 0 | 1,133,171 | 0 | 0 | 1,133,171 | 259,592 | 207,197 |

| North and South America | 12,301 | 0 | 12,301 | 0 | 12,301 | 0 | 0 | 12,301 | 0 | 0 |

| Europe | 8,401 | 0 | 8,401 | 0 | 8,160 | 0 | 0 | 8,160 | 241 | 0 |

| Total | 9,377,173 | 802,090 | 10,179,263 | 3,836,972 | 2,029,102 | 1,990,662 | 0 | 7,856,736 | 2,322,527 | 21,385,735 |

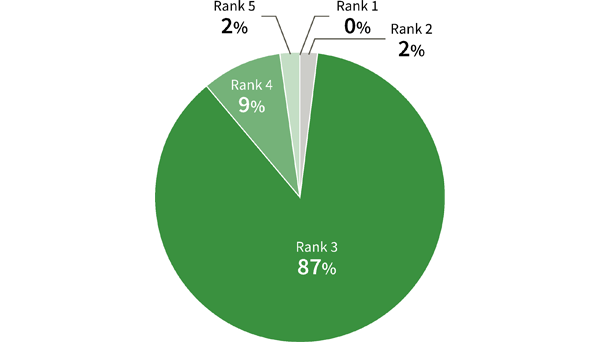

Volume of New Water Used by Water Stress Rank*4 (Fiscal 2022)

Volume of New Water Used in Water Stressed Regions*5 (Fiscal 2022)

(m3)

| Region | Third-party water | Ground-water | Surface water | Seawater | Produced water | Total |

|---|---|---|---|---|---|---|

| Japan | 36,418 | 0 | 0 | 0 | 0 | 36,418 |

| Asia | 844,223 | 0 | 0 | 0 | 0 | 844,223 |

| China | 123,689 | 0 | 0 | 0 | 0 | 123,689 |

| North and South America | 0 | 0 | 0 | 0 | 0 | 0 |

| Europe | 0 | 0 | 0 | 0 | 0 | 0 |

| Total | 1,004,330 | 0 | 0 | 0 | 0 | 1,004,330 |

- *1 Surface water, seawater, and produced water was 0.

- *2 Industrial-use water and tap water.

- *3 Water consumption = Water withdrawal – Effluent.

- *4 Under Aqueduct, each region is assigned a water stress score. There are five levels, from rank 1 (low risk) to rank 5 (high risk).

- *5 Areas with an Aqueduct water stress score of rank 4 or higher.

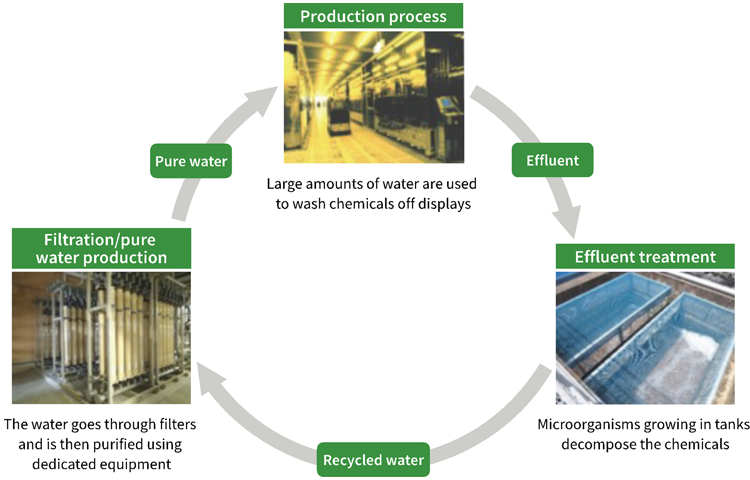

Closed-loop Water Recycling System

The Mie Plant (Taki District, Mie Prefecture) has adopted a closed-loop water recycling system to repeatedly recycle the large amount of water used for the production of displays. The water discharged from the production process contains chemicals that must not be released from the plant untreated. All of this water is collected and goes through steps such as passing through filters and biofiltration (the natural decomposition of chemicals using microorganisms), before being purified with dedicated equipment. The resulting water is used repeatedly in production.

Closed-Loop Water Recycling Flow

Reducing Water Usage at Overseas Bases

At SATL, a production base in Thailand, large volumes of water are discharged from the production process and restrooms. This water was previously released into a nearby river after being properly treated. But now SATL is using newly installed water recycling equipment to purify that water and use it in the production process. The greywater* generated by this recycling process is kept in storage tanks and used for restrooms and for watering the factory’s green areas. SMM, Sharp’s production base in Malaysia, is using rainwater tanks to reduce the amount of water it requires. Large tanks installed in the plant collect rainwater that is used in, for example, air conditioner cooling equipment and restrooms. Thanks to these efforts, SATL and SMM have been able to reduce the consumption of clean water by about 88,000 m3 per year.

- * Water that is unfit for drinking but is not harmful to the human body or the environment.

SATL’s water recycling equipment

SMM’s rainwater tanks