Inspired by Display Structure? AI Olfactory Sensor Development ②

February 6, 2024

In the previous issue, we introduced the background of the development of the AI Olfactory Sensor, highlighting its features and possible applications. In this issue, we continue our discussion with Ms. Teranishi, the driving force behind the AI Olfactory Sensor, investigating measurement principles and the integration of display technology.

– What is the measurement principle of the AI Olfactory Sensor?

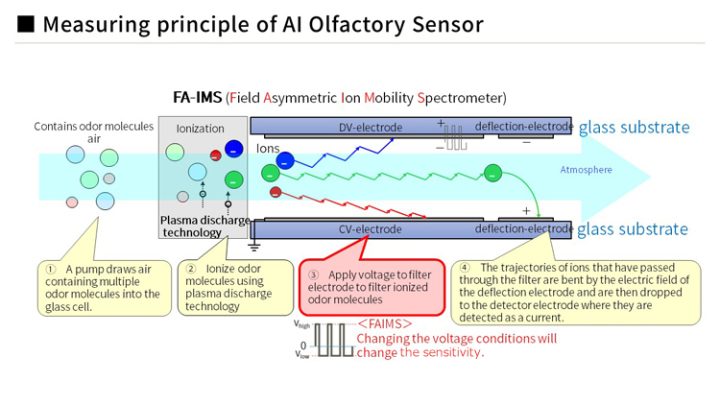

First, let me briefly describe how the measurement process works.

① Air containing odor molecules is drawn in by a pump. →

② Odor molecules are ionized →

③ Ionized odor molecules are filtered →

④ The electric current corresponding to odor molecule ions is detected →

⑤ Detected values are transformed into images →

⑥ Image data is analyzed using AI algorithms

⇒ Odor is distinguished.

The odor molecules ionized by the ionizer ② flow through the narrow gap between the two glass sheets housing the electrodes (positioned to the right in the figure), and when the ionized molecules fall on the detector electrode, they are detected as a weak current.

While somewhat technical, this process involves the application of an asymmetric AC electric field, known as a field asymmetric-wave, within the narrow gap between the glasses. This field causes ions to either travel straight (to the right) and reach the detector, or deflect towards the upper or lower glass electrodes, failing to reach the detector, depending on the mobility characteristics of the ions. An odor usually comprises hundreds to thousands of ions, necessitating the use of distinct field asymmetric-wave applications for detection.

In other words, we measure which molecular ion groups are detectable under specific setting and analyze these differences to determine the odor.

Sharp’s AI Olfactory Sensor employs the Field Asymmetric-wave Ion Mobility Spectrometer method to analyze differences in ion migration velocities, commonly referred to as the FA-IMS method.

– What are the advantages over conventional odor sensors?

There are sensors to measure odor molecules by adsorbing them to a membrane, but it entails a repeated application of heat to desorb the adsorbed molecules. In addition, with continued use, the molecules will eventually stop detaching, leading to a decline in sensor performance.

In contrast, our approach only shifts the direction of odor molecules, ensuring that all incoming odors (molecular ions) are forcibly exhausted. As a result, odor molecules are not deposited on the filter electrodes or detector electrodes, enabling the sensor to be used repeatedly.

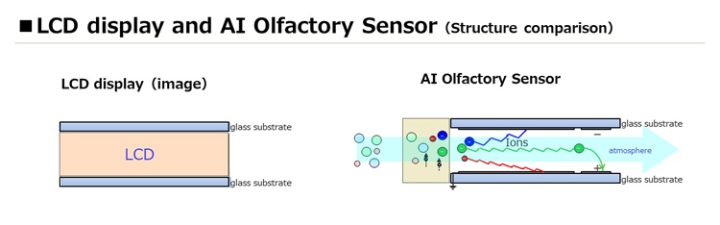

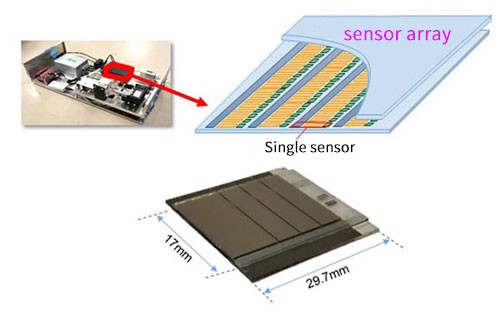

While other sensors that utilize the FA-IMS method typically rely on a small chip with deep-etched ion channels in a silicon substrate commonly used in semiconductors to filter odor molecules, the limited thickness of the silicon substrate results in a very short passage, whereas our method is composed of two sheets of glass, which allows a longer area for the passage, prevents turbulence, and facilitates a smooth ion flow. This design leads to higher measurement accuracy.

– You mentioned that substrate technology for displays are applied for this development?

Yes, the FA-IMS sensor analyzes molecular ions by directing them through a narrow gap. In liquid crystal displays, which I was originally assigned to develop, liquid crystal is applied in between two sheets of glass called the cell. I was inspired by the idea of developing an FA-IMS system wherein molecular ions flow into this cell instead of liquid crystal. What sets apart the unique technology of our AI Olfactory Sensor is the utilization of glass cells for the FA-IMS element, along with data conversion into an image and the integration of AI. As mentioned above, the system not only showcases high accuracy, but also offers cost-effectiveness, leveraging the mass production technology and equipment developed for liquid crystal displays, refined over many years.

– I can’t wait to see it commercialized.

The fundamental principles have been established, and we are now advancing towards commercialization. Our current focus is on expediting the detection process for odors, which currently takes about one minute. Given the tendency of odor components to change easily, we are exploring strategies to shorten the sensing time. This includes initiatives such as augmenting the number of sensors in arrays. Additionally, we plan to promote miniaturization efforts.

– Finally, what are your ambitions for the future?

Aside from the commercialization of the AI Olfactory Sensor, the main mission of our team is to launch new businesses in the non-display field, making use of the elemental technologies of displays. Through the development of the AI Olfactory Sensor, we believe that we have established a framework for launching new businesses. Our aim is to utilize this strategy to produce new businesses successively, one after another.

(Group photo taken at SHARP Tech-Day)

– Thank you very much.

I was unaware that the AI Olfactory Sensor would take advantage of the displays. It’s fascinating to learn that the AI Olfactory Sensor is a product that utilizes the structure of displays. Given Sharp’s expertise in display elemental technologies, I hope the emergence of new intriguing products in the future.

(Public Relations H)

<Related Sites>

■Press Release:

Sharp to Take Part in CES 2024, Major US Tech Event

Sharp to hold SHARP Tech-Day from November 10 to 12

■SHARP Blog