Sharp’s Moth-eye technology is a unique and advanced technology that is more than just low reflection

August 20, 2024

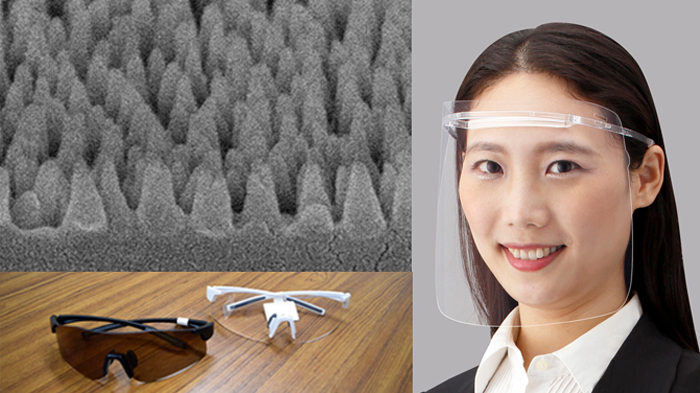

Face Shield by Sharp (right)

Do you know what Moth-eye technology is?

The surface of a moth’s eye is lined with nanoscale bell-shaped protrusions at regular intervals. The nanoscale protrusions have the property of reducing the reflection of external light, allowing the moths to fly freely even in the dark.

Moth-eye technology is a biomimetic technology based on the industrial production of structures that mimic the moth’s eye. Low reflection is achieved by applying a Moth-eye film to the surface of materials such as transparent glass.

Sharp has incorporated such Moth-eye technology into a variety of products, including display panels and face shields.

In addition to low reflection, Sharp’s Moth-eye technology offers other attractive features such as anti-fogging and water repellency. With such features, applying this technology to various outdoor products (such as sunglasses and camera lens filters) is under development.

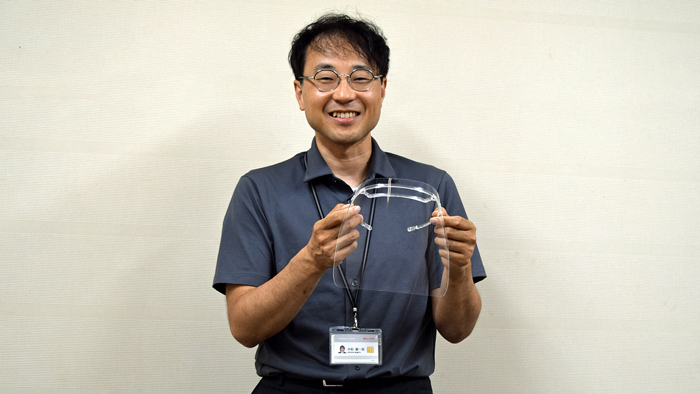

In this issue, we interviewed Mr. Nakamatsu, who is in charge of Moth-eye technology development, about the features and possibilities of Sharp’s unique Moth-eye technology.

(Sharp’s Face Shield with Moth-eye technology in his hand)

― Why does the Moth-eye structure suppress the reflection of external light?

Light reflection occurs between objects with different refractive indices.

The greater the difference in refractive index between objects, the easier it is for light to be reflected. In window glasses, due to this significant difference in refractive index, external light is reflected at the glass surface at the boundary between the two, and unwanted objects, such as your own figure, are reflected.

Because the surface of Moth-eye film has curved and bell-shaped concave/convex structures, the refractive index can change continuously from the surface to the bottom.

Therefore, the application of Moth-eye film on the glass surface reduces the reflection of external light.

― Why has Sharp evolved the Moth-eye technology?

In 2020, with hygiene awareness heightened by the pandemic, Sharp Display Technology Corporation (SDTC), Sharp’s group company in charge of display development, aimed to commercialize face shields in addition to face masks. The low-reflection technology is required in medical treatment and reception areas, which is where we recognized the potential of Moth-eye technology that we have been developing for a long time and having a proven track record in our display products.

However, for face shields, just a low reflection feature is not enough to differentiate from competitors. Therefore, we developed a new material that provides “anti-fogging” function with sufficient mechanical properties, which was well accepted from our customers, together with its low-reflection property.

Since SDTC also aims to develop new business in the non-display field, we decided to further develop the Moth-eye technology.

― So what is Sharp’s Moth-eye technology?

Sharp’s Moth-eye technology achieves low reflection and other features by applying a special process (Making a Moth-eye structure, a bell-shaped concavo-convex structure with minute units of 100 to 200 nm) to the film, which has been cultivated in the development of LCD panels.

A Face Shield with Sharp’s Moth-eye technology achieves very low reflectance below 0.3%, and sufficient anti-fogging.

The moth-eye structure can quickly spread-out water adhere to the surface due to capillary effect and its large surface area compared to flat surface. As the result it achieves “anti-fog” function that prevents fogging caused by condensation and exhalation under temperature differences and high-humidity environments.

When applying hot steam, only the left side without the film will fog up.

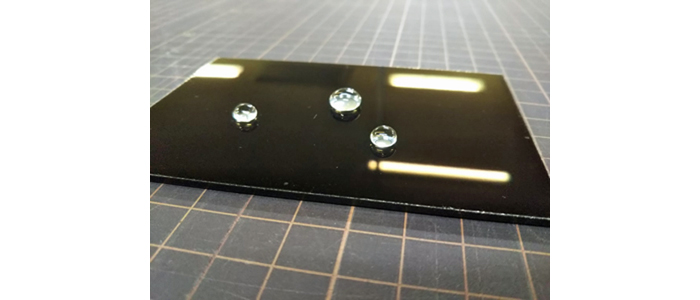

Further research also revealed that by creating a Moth-eye structure with another acrylic resin, it is possible to achieve a water repellent property so that water droplets curl up and roll around like water-repelling lotus leaves, even in the presence of moisture such as rain.

it forms water droplets.

In other words, Sharp’s Moth-eye technology is a proprietary technology that allows products to be equipped with anti-fog or water repellent functions in addition to low reflection depending on the application. In addition, the film uses high transmittance polycarbonate as base material, which provides clear and good visibility.

Furthermore, the film has also proven effective in terms of antibacterial and antiviral *

●Features of Sharp’s Moth-eye Technology

(1)Drastic reduction of external reflection (low reflection)

(2)High anti-fogging

(3)High water repellency

(4)High transparent clear feature

(5)Antibacterial and antiviral performance*

* Effectiveness against all bacteria and viruses is not guaranteed. Results are based on a limited test environment and do not represent results from actual use in real rooms.

― This is groundbreaking. I believe it can be applied to a wide range of products.

It is currently used in sunglasses for outdoor manufacturers, shields for clean wear, anti-fog lenses for diving masks, and anti-fog lenses for ski goggles. Various other applied products are also possible, and some are under concrete consideration, as shown in the figure below.

(Image)

― Were there any particular challenges or difficulties in the development process?

We get a lot of requests from our customers, such as more anti-fog performance. If I go into development thinking “this is how I want it” or “this is how it should be,” I am likely to end up with a product that does not meet the customer’s needs, so I try to develop without being particular. I dare say that may be my obsession.

One of the biggest challenges was developing an anti-fog shield for outdoor use. As we researched, we found that the requirements were quite demanding. Because they are used in highly sealed products, the anti-fog performance used in our face shield was insufficient. In addition, when it rains, it is difficult to see due to the smearing of moisture adhering to the surface. To prevent smearing, water repellency must be improved, but this will lead to fogging. We had to achieve these conflicting requirements at a high level, which made development a difficult task. Through repeated trial and error, such as ordering materials we had never seen before and adjusting the film thickness, we finally found the right combination of materials to meet our requirements. In fact, materials that provide antifog performance absorb a little moisture, and this antifog shield prevents fogging by absorbing a greater amount of moisture.

In this way, we develop materials for use in a wide variety of products by tailoring formulations to product characteristics and needs.

― Finally, please share any personal thoughts you may have.

I want people to know that Sharp has non-electric, non-display technology such as Moth-eye technology. And personally, I want to expand this technology throughout the world so one day I can say, “When it comes to Moth-eye technology, it’s Sharp.”

― Thank you very much.

I was pleased to learn that Sharp still has promising non-display technologies and products based on display element technologies, such as the AI Olfactory Sensor introduced in a previous blog post. In particular, the Moth-eye technology-based products introduced this time are likely to play an active role in our daily lives. Personally I am considering to buy a pair of sunglasses with this technology.

(Public Relations H)

<Related Sites>

■High-performance film with Moth Eye structure(Electronic Components / Display Devices)

■SHARP Blog: